Healthcare

Only absolute quality counts

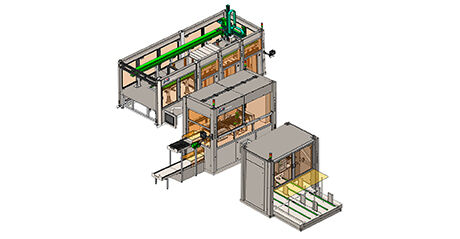

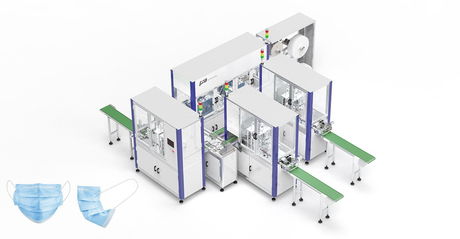

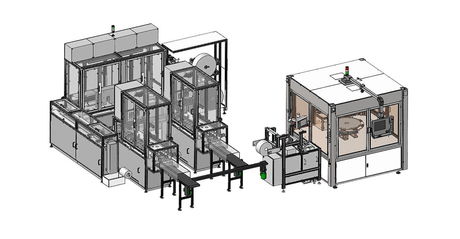

Uncompromising commitment to excellence is the key to the fulfillment of the highest expectations in the areas of patient safety and quality. Here, we have proved that PIA production methods can deliver the highest levels of product safety. Alongside conventional, customer-specific solutions, PIA Automation also offers meditec®, an innovative product line for integration in medical systems. These products fulfill strict hygiene requirements and are the first medical-technology assembly systems to have been assessed and approved for use in clean room environments by the Fraunhofer Institute.

meditec® unites sophisticated assembly tasks with compact, clean-room-approved design and fulfills the most stringent documentation requirements. The assembly systems demonstrate a high degree of standardization and enable short time-to-market cycles.

Healthcare

Assembly portfolio

- Medical mouth sprays

- Syringe filters

- Drip chambers

- Pill dispensers

- Lancet drums

- Transfer needles

- Syringe handling

- Auto-injectors/Insulin pens

- face masks

- Blood gas analysis systems

- Reagent containers

- Capillary blood samplers

- Blood sample filter attachments

- Inhalers...

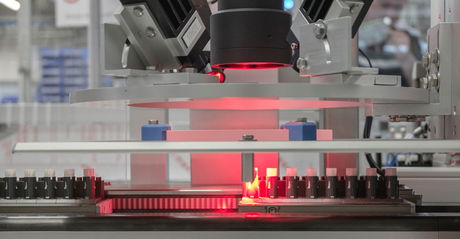

Special Processes

- precision filter stamping

- heat sealing

- liquid media dispensing

- siliconization

- separating, placing and glueing needles and tubes

- ultraviolet curing

- ultraviolet sterilizing

- ultrasonic welding

- laser welding

- assembling springs and membranes

- product marking

- leak testing

- flow testing

- electrical testing

- functional testing

- optical testing

Medical brochure

Questions?

Get in touch with us

You can quickly reach your contact person for the automated production of healthcare products here:

Reference Customer

everything is possible!

- Sanofi

- Gerresheimer

- Berry Formatec

- Roche...

Medical Division

COMPREHENSIVE MEDICAL SOLUTIONS

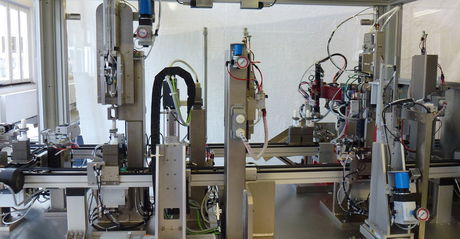

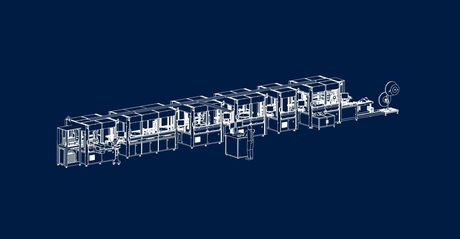

In this sector, PIA offers a wide range of individual production equipment of the highest standards. In addition to the Meditec® cleanroom modules, we have more production modules available. These include turnkey production facilities, test systems and laboratory automation for liquid and solid-state products.

OUR EXPERTISE STARTS IN PRODUCT DEVELOPMENT ALSO IN THE MEDICAL SECTOR

In particular, we offer the rapid and efficient implementation of auxiliary devices that are required for pre-series production or for products at the development stage. Our flexible solutions for new and innovative products in the medical sector can be implemented for different cycle times in a scalable and process-safe manner.

INTEGRATION OF SOFTWARE & MECHANICAL AND ELECTRICAL SUBSYSTEMS

In addition to in-house expertise in innumerable technological areas, we are also specialized in the integration of mechanical, electrical and software-based subsystems. Depending on customer and product requirements, our systems are designed in the desired or required cleanroom classes.

With PIA you have a comprehensive competent contact partner for the entire production process of medical technology. Our range of services extends from design, prototyping, mechanical and electrical construction to programming, commissioning and production ramp-up – from hand-held devices to complex, fully automated facilities.

Modular system concepts that support different levels of automation are also part of our portfolio.