Case Study: Healthcare

Highly flexible finale assembly of auto-injectors

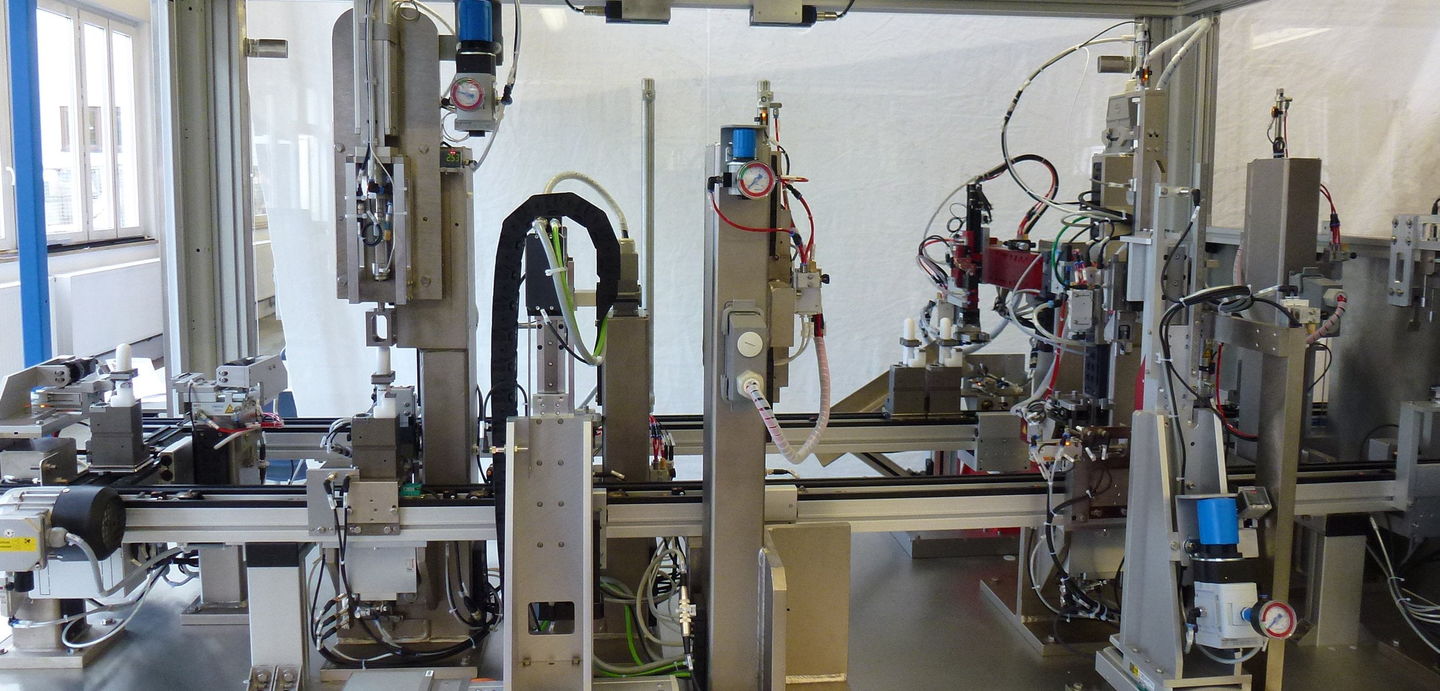

Highly flexible semi-automatic production line for the final assembly of various auto-injection systems.

In this production line, the workpiece carrier is loaded manually. The production cycle rate is 15 parts per minute.

Processes:

- Force-displacement-monitored insertion of the syringe into the front assembly

- Inserting the power pack

- Compressing the power pack with the assembly

- Camera inspection for correct assembly

- Labeling of the auto-injector