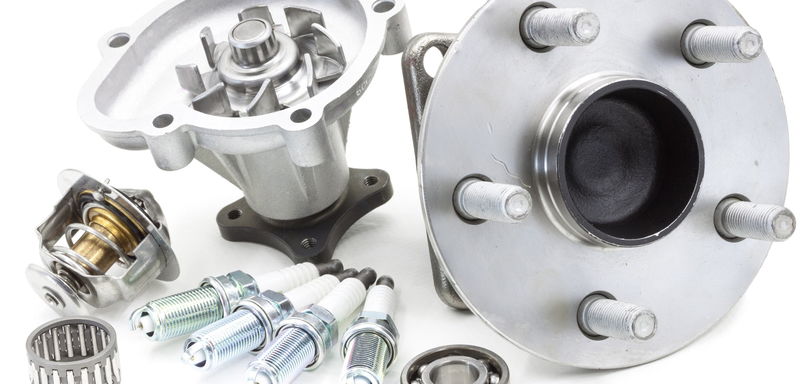

Components

We take on every challenge

Automobile manufacturers are constantly developing new components that have to function smoothly for many years. These are components as diverse as the 4-zone air conditioning system, adjustable mirrors and seats with memory function. Small size, minimum weight, long service life and optimized energy consumption are just a few of the features expected by the automotive industry.

Reliable and safe implementation of complex assembly processes.

One main task is to check and guarantee the quality and functions of components during assembly processes that can often be very intricate. In terms of product and assembly equipment, the most complex phase is the moment of assembly – so the assembly and testing systems must perform perfectly. PIA specializes in the development of measures that secure processes during product development – and then delivers production systems that run with reliable productivity.

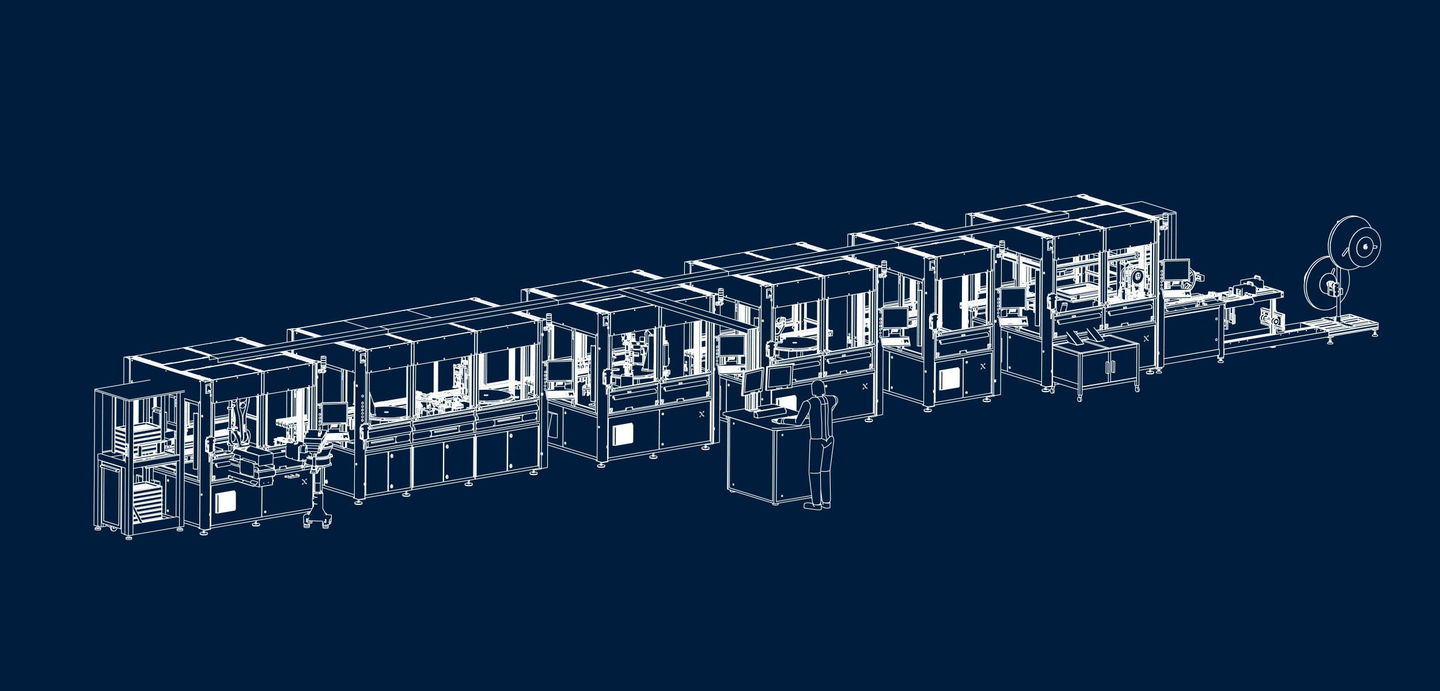

Assembly lines

In the world of assembly and production line systems, the main focus is on quality assurance, process reliability and traceability.

From individual manual workstations to complex manufacturing and production line systems, safe and smooth production is essential in the automotive industry – and for decades now, this has been a matter of course in our perception of automation. Our production concepts meet the requirements of logistical data acquisition and recording, as well as those of production processes that run without the need for retooling. Our standardized modules help to reduce costs and project lead times. We create flexible and individualized overall solutions for our customers, using various interlinked stations such as transfer systems, rotary indexers and robots.

Testing and end-of line tester

Perfection down to the smallest detail: from the haptic testing of rotary actuators to complex electrical tests.

PIA has many years of experience in the field of measurement and testing technology. This know-how guarantees our customers perfect products and reliable quality assurance. All functions of the product are tested. The environmental conditions are simulated, and the reaction of the test object is recorded, documented and evaluated. The aim is to maximize the test throughput in series production and to minimize the cycle time. We use high-performance software for this and are constantly developing the procedures.

Solutions for everything

More comfort, more intelligence, more performance. PIA versatility extends and increases value creation.

In the automotive industry, innovative concepts are being developed in ever shorter cycles that require completely new components and functional carriers to be integrated into the vehicle architecture. The keywords here are e-mobility and autonomous driving. The range of assembly products is enormous: Operating elements, control electronics, driver assistance systems, sensors for temperature & humidity, multifunctional switches and much more must be developed quickly and reliably, serially produced and installed in the vehicles.

PIA has experience with the most diverse components and possesses extensive know-how in the processes that are used:

- Water and oil pumps

- Air and vacuum pumps

- Diesel pumps

- Actuators

- Heating, ventilation and air conditioning systems

- Vehicle seats

- Door hinges

- Refueling systems

- Fan clutches

- Suction tubes

- Hydraulic valves

- Light switching centers

- Antenna amplifiers

- Roof antennas

- Control electronics

- TV tuners

- Compenser plugs

- Driver assistance systems

- Pedal sensors

- Air conditioning, operating and control devices

- Audio amplifiers

- Humidity sensors

- LED lighting systems

- DC motors

- EC motors

- Mirror drive systems

- Ignition and glow plugs

- Rear spoiler assembly (Class A surface)

Questions?

Get in touch with us

You can quickly reach your contact person for the automated production of COMPONENTS for the automotive industry here: