NEXT GENERATION FLEXIBILITY

PIA‘S SOLUTION FOR COMPONENT HANDLING

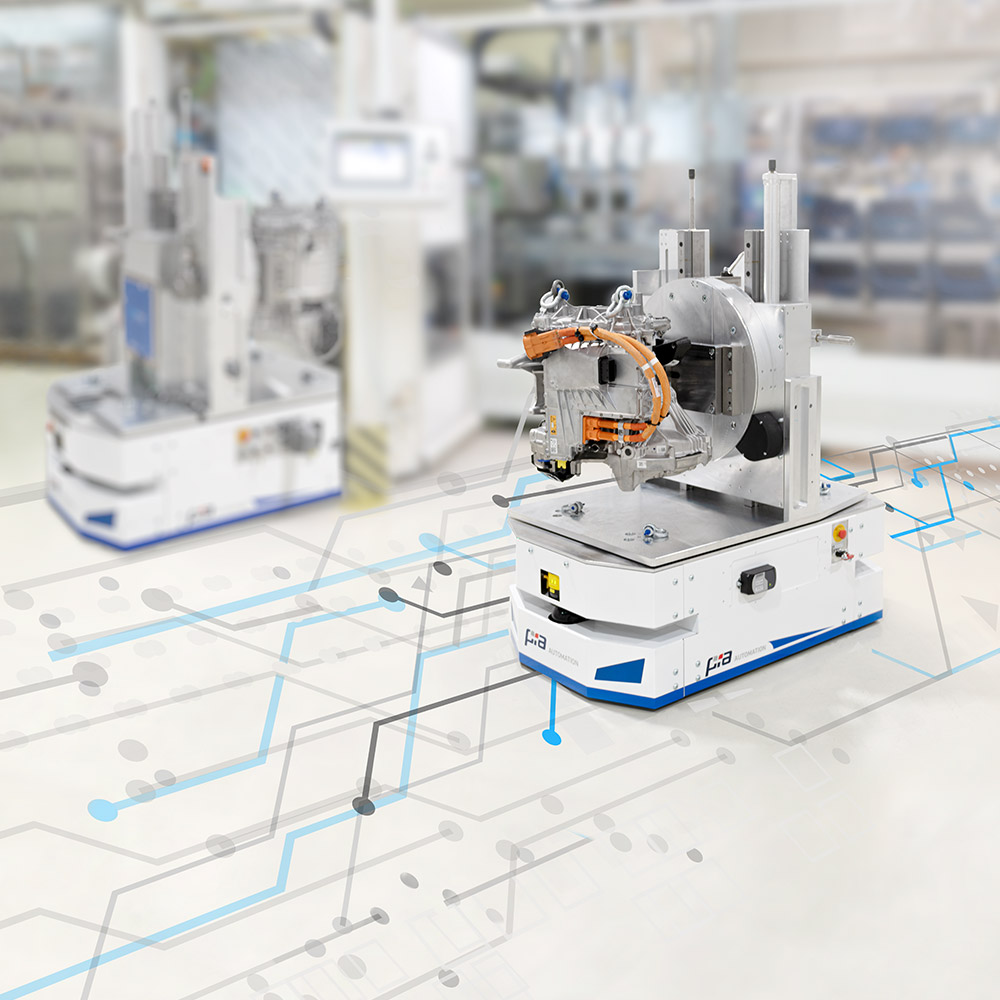

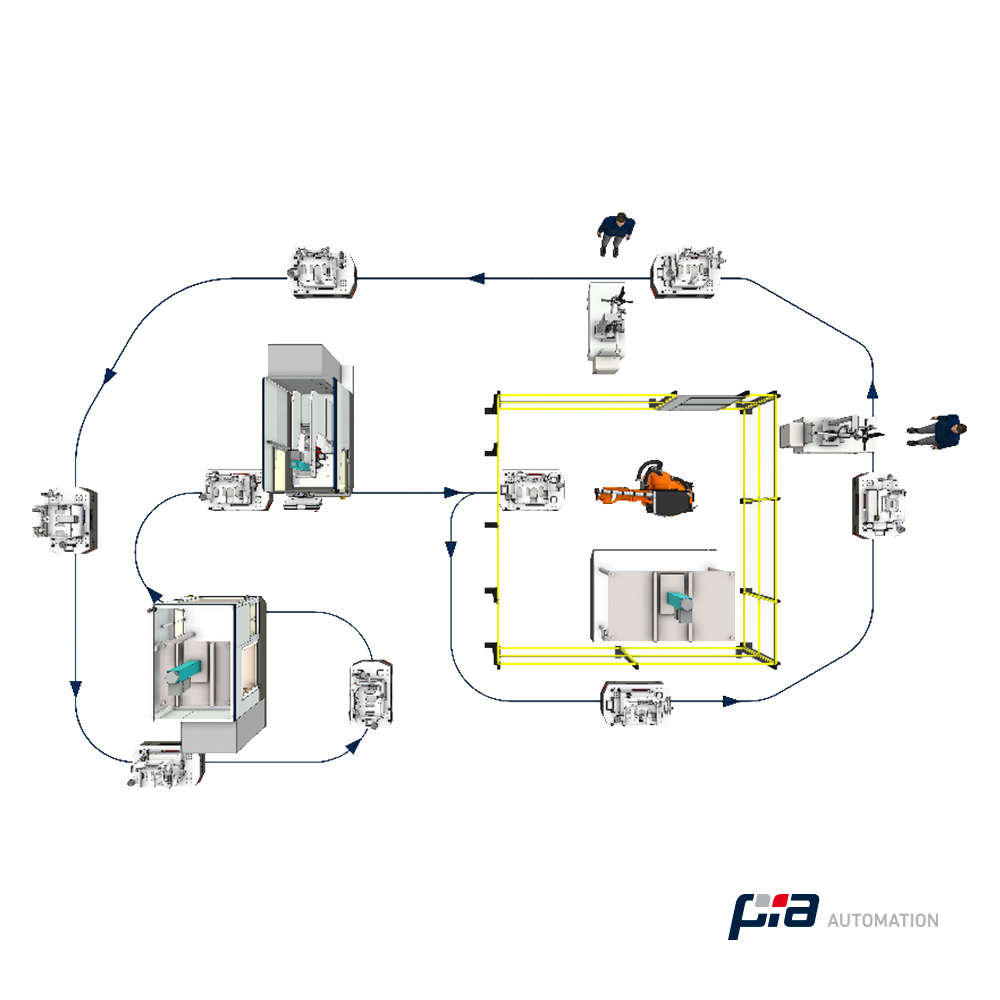

To produce e-mobility components, PIA has developed the concept of partially automated and flexibly linked assembly cells. These cells result in a future-proof system which - due to short-term product changes and a large variety of part types - is prepared for the integration of further units. The use of the piaAMR, which is optimally adapted to customer requirements and the system environment, rounds off PIA‘s portfolio and position as a complete solution provider. It was necessary to develop our own solution because the systems available on the market do not meet the complex requirements: They are mostly rigid logistics solutions with a low load capacity. In contrast, the piaAMR represents an advanced solution for component handling: the AMR as a mobile workpiece carrier or workstation. Areas of application are in the automotive industry as well as in assembly and production (component transport, material provision) or logistics in other industries.

KEY DATA OF THE AMR

- Load suspension device: workpiece-specific, height adjustable, swiveling ± 180°, Payload: up to 2204 lb.

- Battery charging technology

- Cycle time parallel inductive fast charging in the

station for 24/7 operation - Maintenance-free Li-ion battery with a service

life of up to 15 years or 17,000 charging cycles - Scalability of the battery capacity

- Cycle time parallel inductive fast charging in the

- Positioning accuracy

- +/- 10 mm with free navigation

- +/- 3 mm by means of fine positioning

- +/- 0.1 mm for workpiece pallet excavation

- On-board display: query of diagnostic data and battery charge level

- Hand control device for manual control

- Emergency recovery: Rescue pack (offline battery), mechanical towing device

- Safety concept: real-time personal protection through laser scanners and step rails

ADVANTAGES OF THE AMR

MAXIMUM FLEXIBILITY IN TERMS OF...

- Layout

- Size

- Load capacity

- Load suspension devices

INNOVATIVE CHARGING CONCEPT

- Inductive fast charging „in-process“

- Maintenance-free Li-Ion battery

- Simple charging stations

SUSTAINABLE USE

- Simple and quick adaptation to changes in production

- Commissioning of additional AMR without additional installation effort

- Reusability for new tasks

FREE NAVIGATION

- Localization via laser data (without additional auxiliary technologies)

- Independent avoidance of obstacles and dynamic adaptation of the route

Download

LOCALIZATION AND NAVIGATION

- Software solution for autonomous control of AMR fleets

- Localization technology: Simultaneous localization and mapping (SLAM) using laser scan data

- Fleet management for efficient, quantity-optimized use

- Worldwide tried and tested system

- 80 international projects, 400 smart vehicles, 800,000 kilometers traveled

- Customers from the automotive, e-commerce, health and intralogistics

QUESTIONS?

GET IN TOUCH WITH US

You can quickly reach your contact person for the internal transfer systems of the future: