Industry 4.0

The new industrial revolution

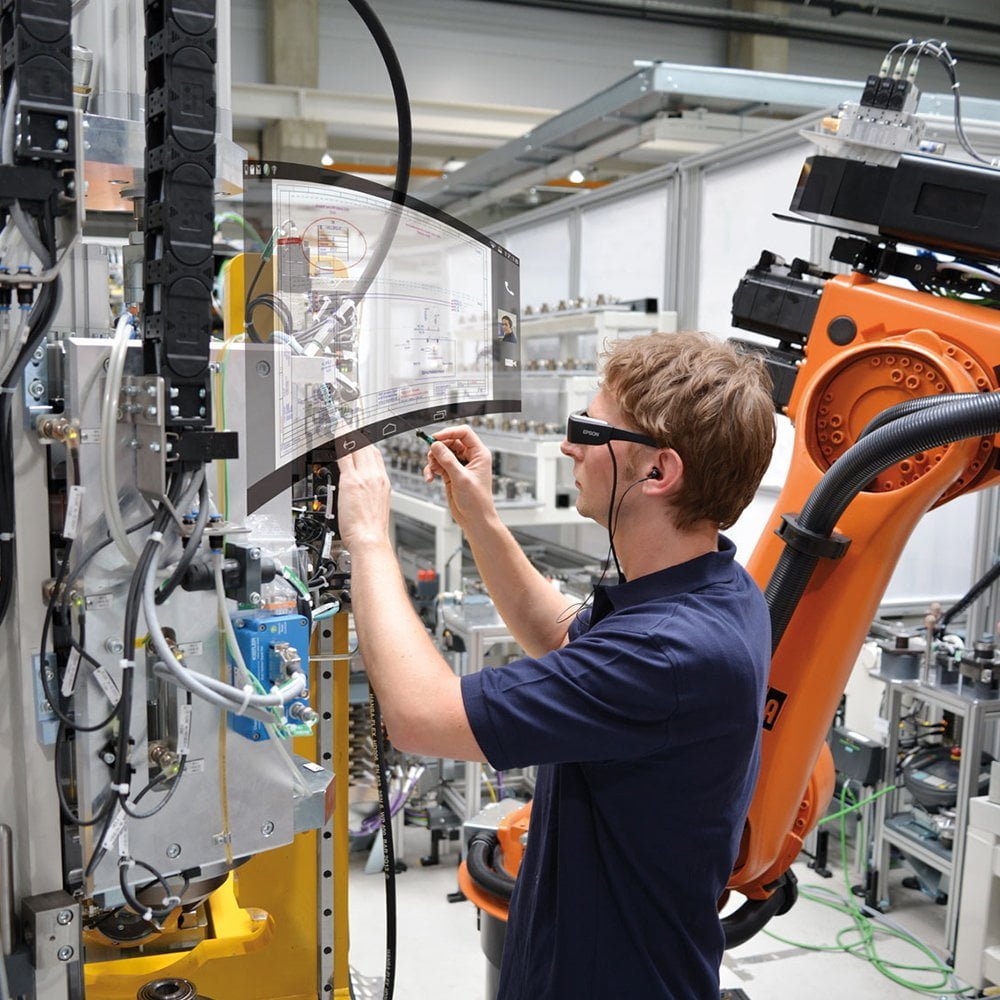

Automation is one of the key concepts in the digital transformation process and we believe that this is a new chapter in industrial manufacturing that hasn’t been seen before. High levels of connectivity will make machines – and even entire production facilities – intelligent and, in turn, more controllable, more adaptable, and even capable of autonomous learning. The limitation of “one machine, one product” now belongs to the past. A highly integrated, networked manufacturing process enables greater flexibility and ground breaking improvements in the efficiency of production methods.

The intelligent connection of automated production with the supplier network and the service network will provide immense advantages to all industries. PIA Automation consistently uses the advantage through networking and has integrated „Smart Production“ or also Industry 4.0 as an important asset in the company.

PIA Automation offers proven tools for high-end Industry 4.0 solutions.

PIA Automation uses VR to create a virtual immersive experience where you can enter your future plant in advance and see it from different and new angles.

PIA Automation offers an ecological alternative to plant inspection. This allows you to perform ergonomics studies without traditional cardboard box construction.

PIA Automation offers acceptance tests and analysis during the project phase through new visualization possibilities.

PIA Automation offers interactive training opportunities without plant downtime.

PIA INDUSTRIAL APP SUITE

ADVANTAGES

- Increase of production transparency of all plants

- Identification and elimination of bottlenecks

- Detailed problem analyses with little time expenditure

- Assurance of traceability

- Professional reporting without additional effort

- Global overview at every level of detail

- Intuitive detection of systematic deviations

- Benchmarking with just a few clicks

VR TECHNOLOGIES

ADVANTAGES

- Improvement of communication

- Time saving through early decision making

- Cost avoidance through early optimization

- Objective ergonomics analysis

- Detailed representation of the virtual machine

- Early familiarization for the operators

- Minimization of training on the real machine

- Motivation of training participants through innovative training methods

- Shortening of the time to running production

Questions?

Get in Touch with us

You can quickly reach your contact person for high-qualitity Industry 4.0 solutions here: