Meditec - Modules

flexible process module

- Modular concept - flexible grid dimension 1200 mm

- Drive components with small footprint

- Intelligent transport system

- Individual control is possible (Siemens, B&R, etc.)

- Numerous reports (AuditTrail, Batch Report, etc.)

- Integration of PIA 4.0 digitisation solutions are possible

Meditec - Modules

FLEXIBLE MANUAL WORK STATION

- Flexible use of different processes (e.g. pressing, laser, adhering, etc.)

- Short retooling times for different variants

- Fast production of clinical samples - short time to market

- Numerous reports of process and machine data

- Flexible connection to customer‘s IT systems

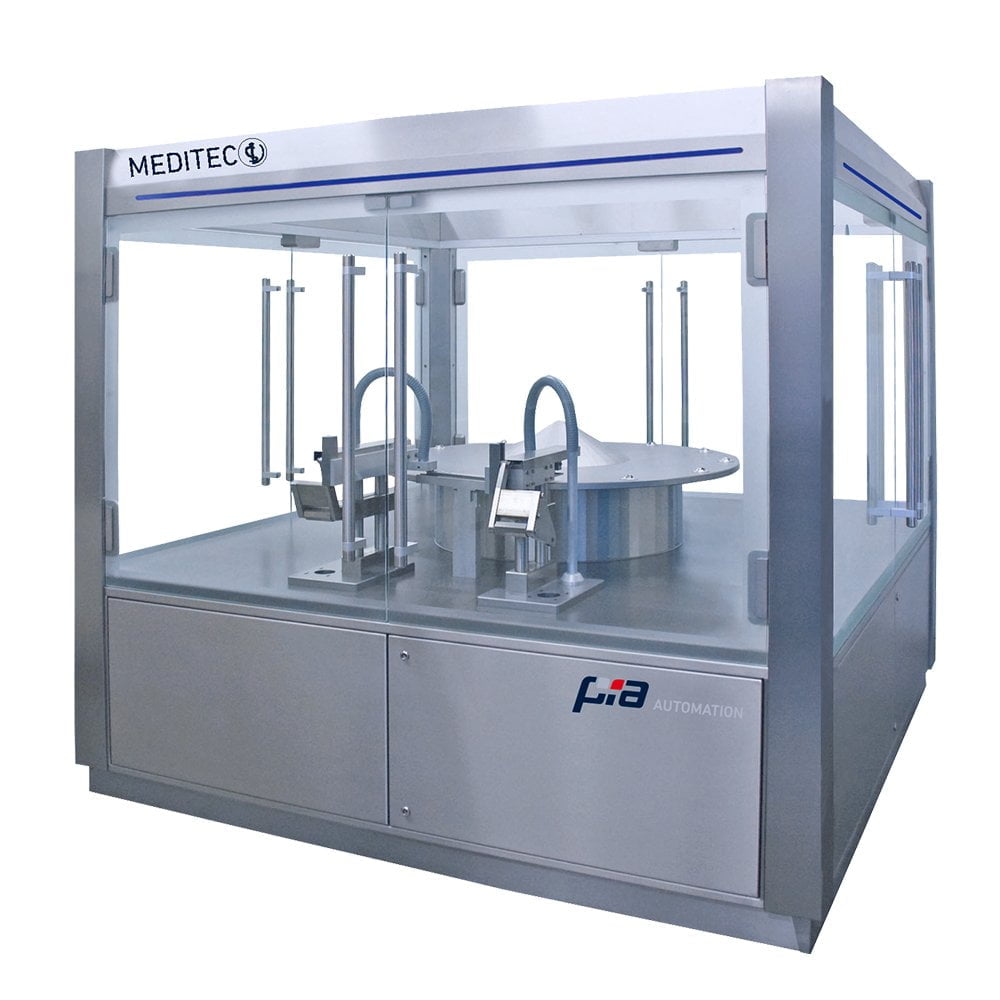

Meditec - Modules

Semi-Automatic

- perfect for small batches, clinical trials and process validation

- manual loading and unloading, up to 20 cycles per minute, up to 4 process and testing stations

- up to clean room ISO-class 6, can be upgraded to full automation

- open for new applications and types, quick integration of new processes

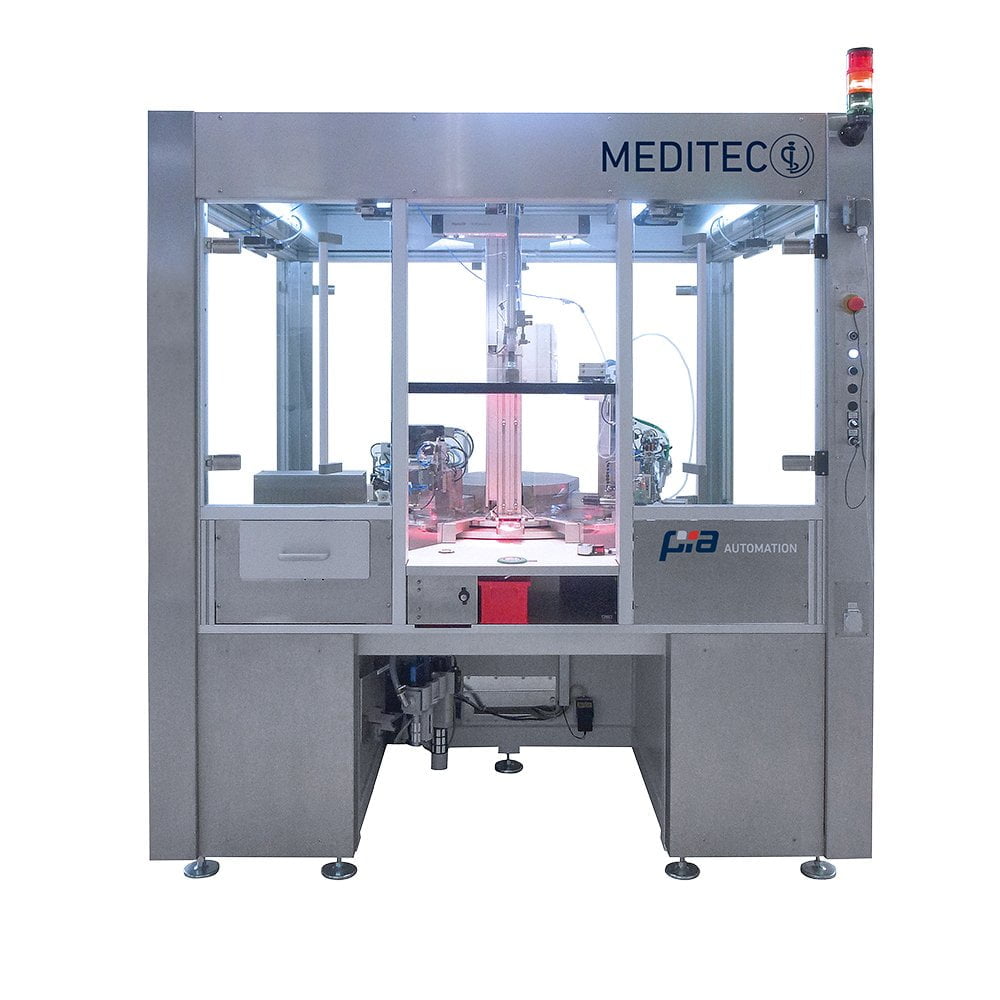

Meditec - Modules

ROTARY INDEXING SYSTEM

- perfect for the quick assembly of components

- station drives beneath base plate, up to 60 cycles per minute, 1–8 lane feeding tracks

- up to clean room ISO-class 6 , capable to handle components up to 80 mm

- minimum floor space requirement

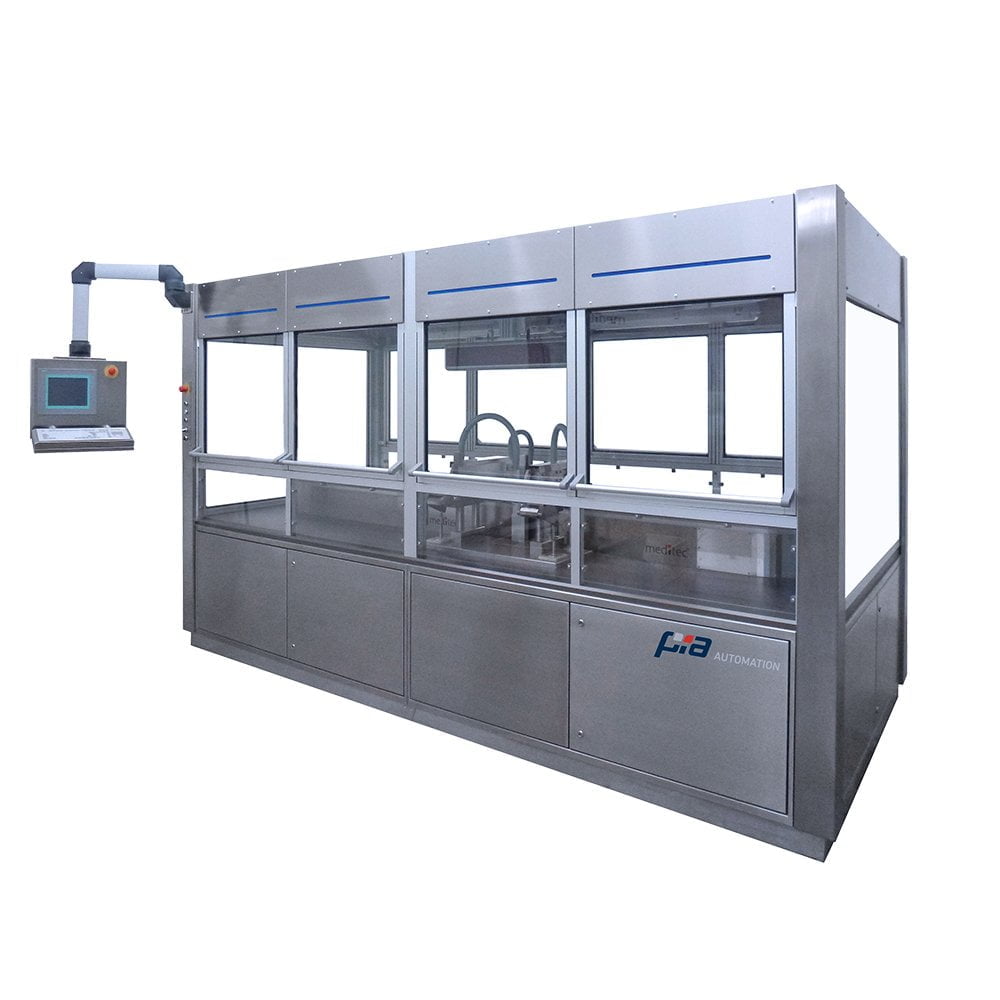

Meditec - Modules

LINEAR TRANSFER SYSTEM

- perfect for the complex and quick assembly of components, modular extendable

- up to 200 cycles per minute, work piece carrier transport with variable processing times

- up to clean room ISO-class 6, capable to handle components up to 60 x 160 mm

Meditec - Modules

MEDITEST SYSTEM

- perfect for the final test of pens or autoinjectors with active ingredient

- torque, force, displacement, gravimetric and optical tests, clean room ISO-class 8

- unmanned operation, extended autonomy with additional palletizer

Meditec - Modules

Options

- integrated control cabinet

- ESD design

- PIA clictec®

- combinable with further automatic cells

- laminar flow unit

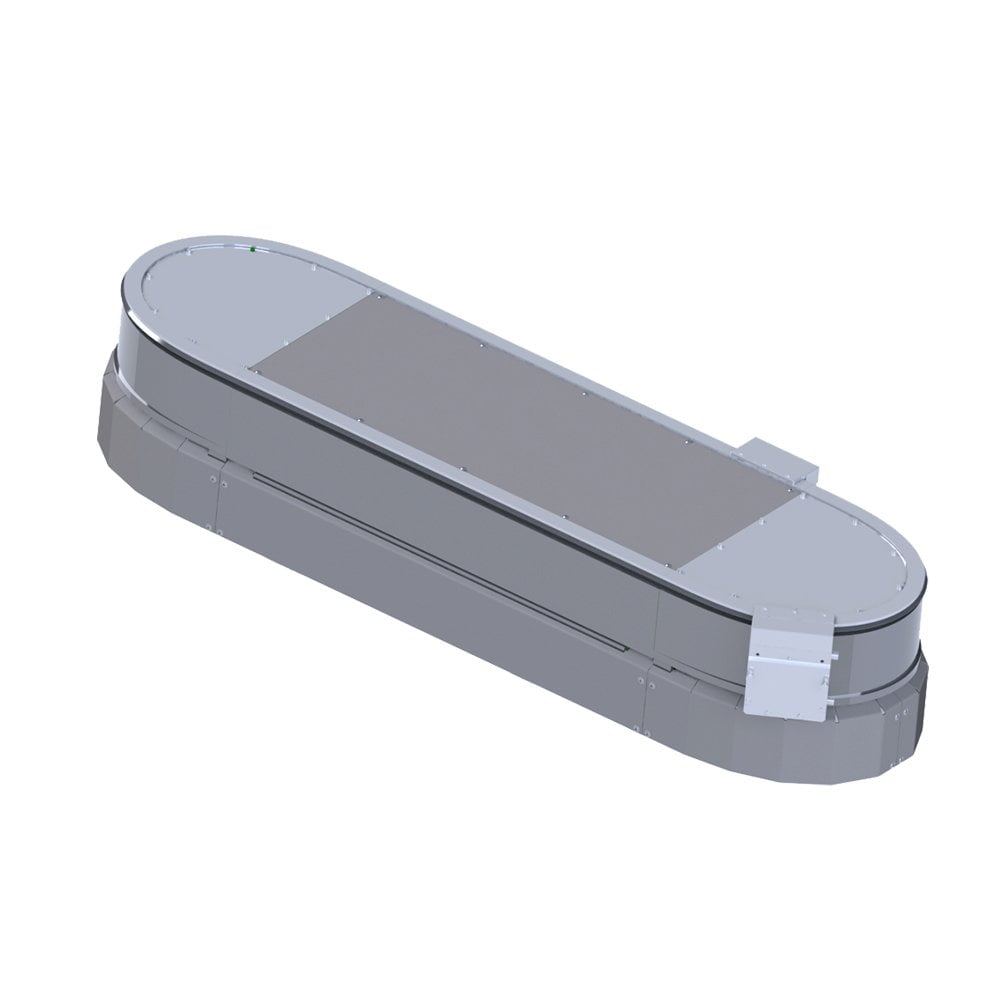

Meditec

DRIVE SYSTEMS

To transport components between single processes PIA Automation uses workpiece carrier systems, rotary indexing tables and highly dynamic and flexible linear direct drive systems. The drive systems themselves and the interaction with further PIA meditec® solutions provide a costeffective assembly system for different cycle times perfectly usable in GMP regulated environments.

Meditec

PICK & PLACE HANDLING

To handle components according to GMP PIA Automation uses handling systems developed inhouse or conventional systems qualified for medical applications. The handlings are designed to avoid movements above components. Process and component specific movements above parts will be covered accordingly ruling out contamination of parts. Closed surfaces and low dead-space design provide cleaning ease. meditec® pick & place handlings can be equipped with servo drives, cam drives or pneumatic cylinders according to task and cycle time.

Meditec

HMI/SCADA SOFTWARE

Software validation and compliance with international rules (e.g. FDA CFR Part 11) play an important role in medical technology. Therefore PIA Automation counts on well-proven and standardized software products which meet all requirements and can be adjusted according to

customer demands. The innovative user interface offers an intuitive operation and allows a quick overview of various relevant machine and process data.