Case Study: Healthcare

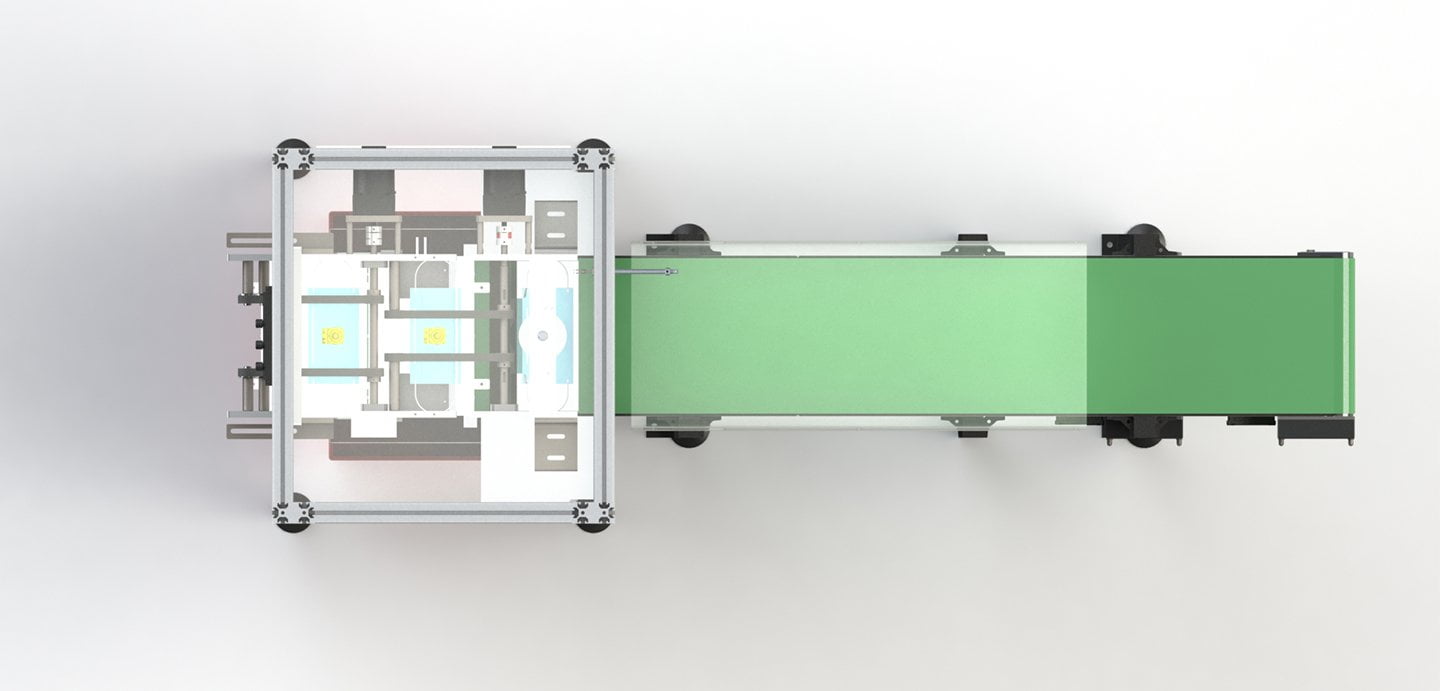

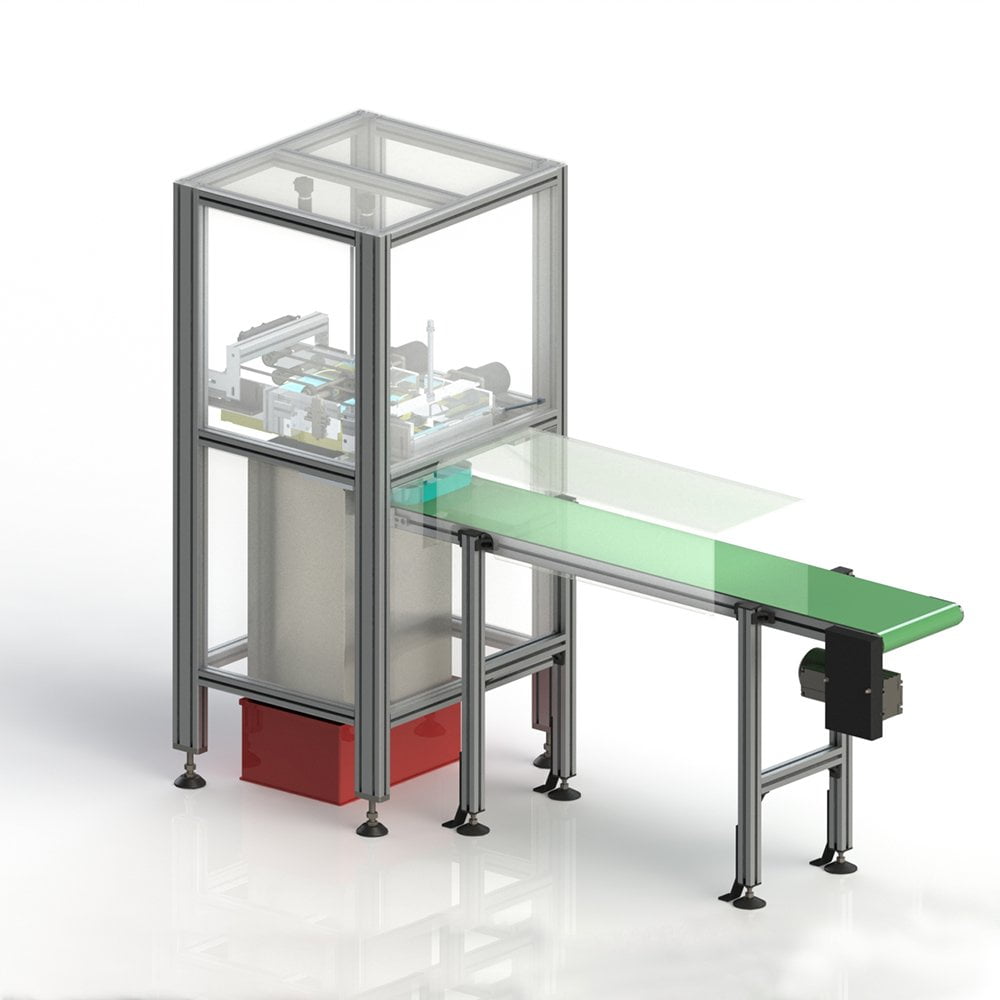

EOL-Tester for face masks

Test systems from PIA Automation are implemented in numerous industries and set high standards in terms of precision and quality. Independent of fully automated test concepts with low cycle times, PIA's product and service range now also covers mask test systems. With many years of experience in the field of automated assembly and testing of medical devices, PIA Automation is predestined for your individual applications.

This compact solution can be implemented into an existing system with little effort. The extended testing module does not influence the machine performance and facilitates quality testing.

Process workflow: The masks will be fed to the testing module through the existing outfeed conveyor. A camera arranged vertically checks the folding, the welding quality and the presence of the nose wire by transmitted light. The mask will be transferred to a second belt drive and the ear band and edge welds will be checked. IO masks are placed on the outfeed belt with the usual stacking unit. NIO mask are being discharged into a NIO box via a foldable NIO output.

Advantages:

- Development, production, support and know-how from one source (one-stop-shopping)

- Retrofit table concept

- Compact design

- Renowned vision system in use (Keyence)

- Automatic bad part separation

- Accessibility still guaranteed via safety gate

Convince yourself and have your produced masks checked automatically!

Questions?

Get in touch with us

You can quickly reach your contact person for the automated packaging of face masks here: