Powertrain

PIA power for more productivity

PIA’s modular production units comprise all the machines and equipment needed to assemble and test powertrain assemblies.

We have co-written automotive history in this sector. Numerous technology developments in the powertrain are based on automated processes that have been developed and refined by PIA.

Our most important motivation is to combine innovative production technologies with technically mature solutions and to open up new ways for our customers to achieve reliable productivity.

- Laser welding cells

- Assembly line systems

- EOL-Tester

- Electrical modules for hybrid vehicles

- Industy brochure

Laser welding cells

PIA supplies complete solutions for the manufacture of powertrain components in all aspects of laser welding

In addition to their fast and flexible properties, total solutions from PIA also offer maximum process reliability.

Welded connections make it possible to significantly reduce size and weight in the design of components, reducing the manufacturing costs of complete aggregates. The use of lasers in welding processes – especially the use of solid-state lasers – can open up more cost-cutting potential in production.

Safe use of these laser technologies is essential for long-term success – and PIA Automation offers innovative solutions that guarantee the quality of the processes and are known for their high degree of process reliability.

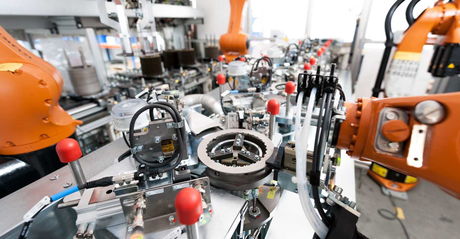

Assembly line systems

The powertrain sector is a specialty of PIA Automation and includes a wide range of components.

Our extensive experience with production environments for powertrain production makes our technology portfolio in this sector predestined for future concepts in the field of e-mobility. Short development times in combination with proven test methods lead to a fast serial production run.

We have developed production solutions for the following powertrain components:

- Dual clutch

- Torsional dampers

- Hybrid drive modules

- Front- and rear-wheel drive modules

- Transfer transmission

- Power take offs

- Transmissions

- Torque vectoring units

- Wheel hubs

- FDU & RDU assemblies

- Camshafts

- Balance shaft units

- Turbo chargers

- Rocker covers

- Oil sumps, piston cooling systems

EOL-Tester

End-of-line-Tester - flexible test systems

For many years now, electronics have been used more and more in numerous products.

End-of-line tests are therefore essential for every manufacturer to minimize risks and ensure the safety and satisfaction of users. To ensure test coverage at the highest possible throughput, you need a flexible test solution from PIA Automation.

Test systems from PIA set high standards in terms of precision and high quality. The portfolio ranges from complete end-of-line test fields to in-line testers integrated into the assembly process. Independent of fully automated test concepts with low cycle times, PIA's product and service range also covers the development and manufacture of audit test benches with maximum product flexibility.

Electrical modules for hybrid vehicles

E-components in hybrid concepts are subject to special requirements for which we offer tried & tested solutions.

The combination of internal combustion engines with an electric drive requires a completely new approach to the design of the powertrain. Vibrations, waste heat from the combustion engine and mechanical loads on the transmissions place high demands on the electric motor and the electric modules. At PIA, we have developed an expandable and highly variable solution principle for their production: semi-automated assembly cells linked by conveyor belts and buffer carts, resulting in an extremely expandable and flexible concept, which is ready for the integration of further units.

Industy brochure

In the powertrain sector, we offer a comprehensive portfolio of processes and tests:

- Assembly layouts based on lean aspects

- Value stream analysis

- Flexible employee deployment

- Scalability

- Laser beam welding

- Drive set adjustment stations

- Dynamic torsional backlash testing

- Collar nut bolting

- EOL tester (structure-borne sound and function)

- Standardized process or function modules

Questions?

Get in touch with us

You can quickly reach your contact person for the automated production of POWERTRAIN components for the automotive industry here: