Disposable face masks

Optional packaging solutions

The packaging module by PIA Automation for the final packaging of the (filtering) face masks can be individually adapted to customer requirements. In order to guarantee efficient delivery times, there are already developed standard modules.

ADVANTAGES OF STANDARD MODULES

- Short delivery time

- Reliable packaging concept with low maintenance requirements

- Modular design, simple and safe operation, automatic alarm system

- Integrated intelligent operating system, one-man operation

Packaging option (foil)

SEMI-AUTOMATIC FOIL PACKAGING

The tubular film gets first a bottom seam and a perforation. Afterwards the opening will be established by an air blast, the bag is held by two fixing clips and a spread unit establishes the simple insertion by wide the opening. After insertion of the masks, the air in the bag reduced by a foam plate and the bag is welded and cut. The finished bag is falling down in e.g. in a box. The next bag is prepared and brought into filling position.

TECHNICAL DATAS

- Packaging speed for the machine up to 15 bags/minute with tubular film

- Insert opening: 400mm width x 125 mm

- Foil material/thickness: PE, OPP, 40 – 200 μm

- Max. diameter foil roll: 300 mm / Max. foil width: 400 mm

Packaging option (foil)

AUTOMATIC FOIL PACKAGING

The efficient full-automated tubular film packaging machine process by using a forming collar for a three side welded foil packaging of the masks. The single packaging units will be integrated direct at the output of the ear band welding modules and can process single masks up to stacks of 30 masks by working at the same speed as the mask production line.

The packaging process starts by transporting full automated the masks from ear band welding to the stacking unit. Depending on the stack, the number of masks will be displaced above each other through a mechanical funnel or transported single by single. The masks will be scanned to ensure the correct length and transported through forming collar which “lays” the tubular film around the masks.

Afterwards the bag is welded precise in lateral and cross direction and will be transport by another conveyor belt from the system to a carton or KLT As an option, a label printer can be added per system which displaces a label on the bags.

Technical datas

- Packaging speed for the machine up to 40 bags/minute with tubular film without labeling

- Packaging speed for the machine up to 25 bags/minute with tubular film incl. labeling

- Package good height: max. 250 mm

- Package good length: min 75 mm

- Foil material/thickness: PE, OPP, 30 – 60 μm

- Max. diameter foil roll: 400 mm

- Max. foil width: 680 mm

- Label size (l x w): max. 100 x 80 mm

Questions?

Get in touch with us

You can quickly reach your contact person for the automated packaging of face masks here:

Packaging option (Folding box)

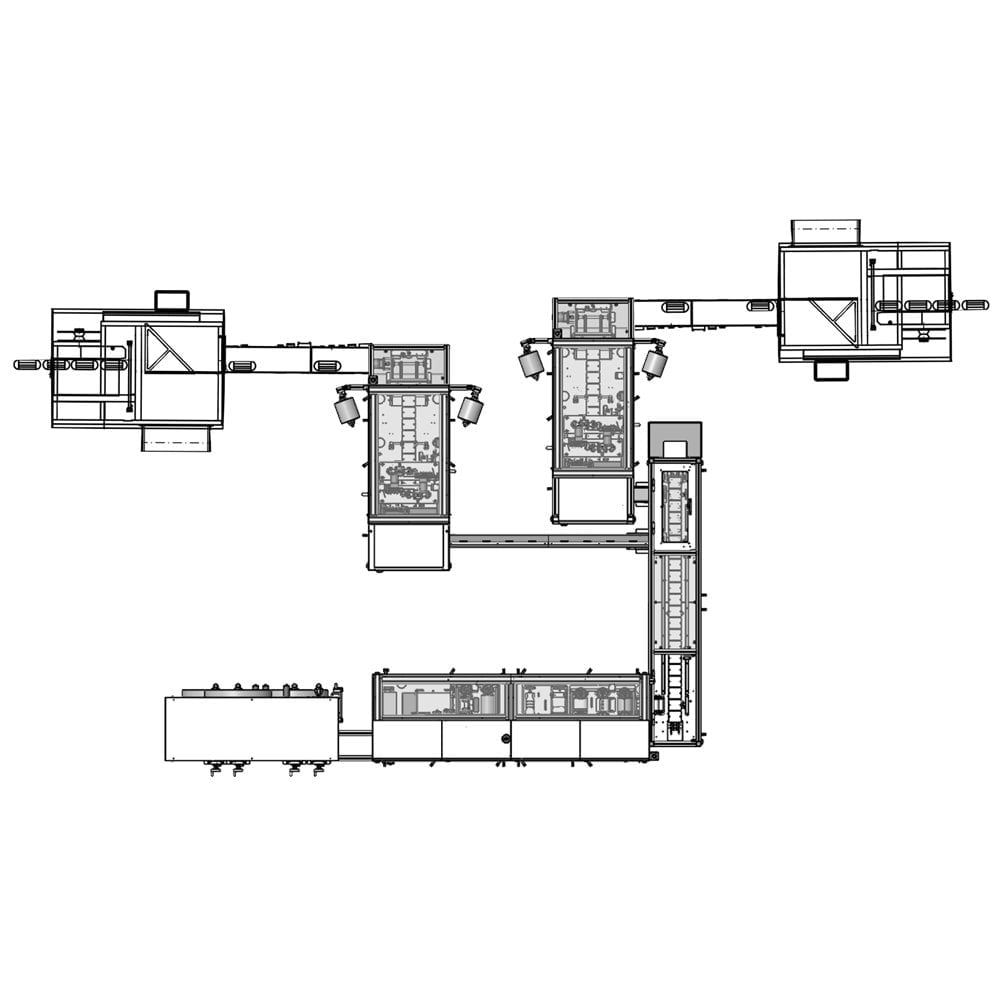

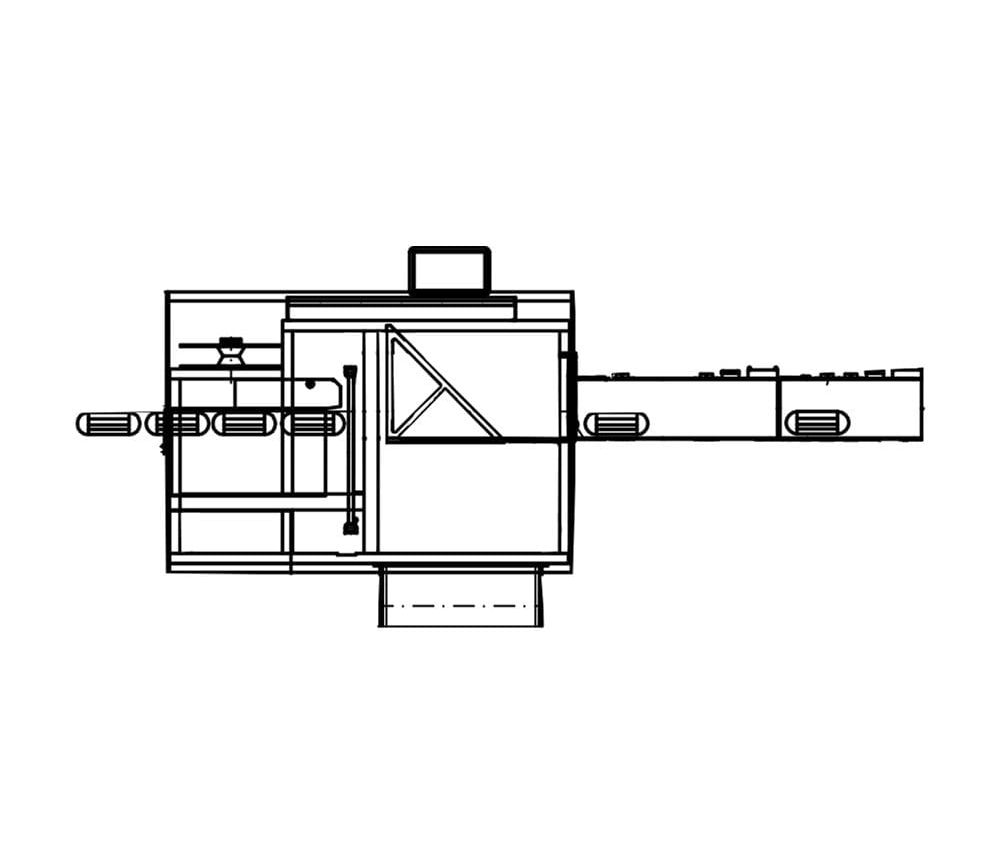

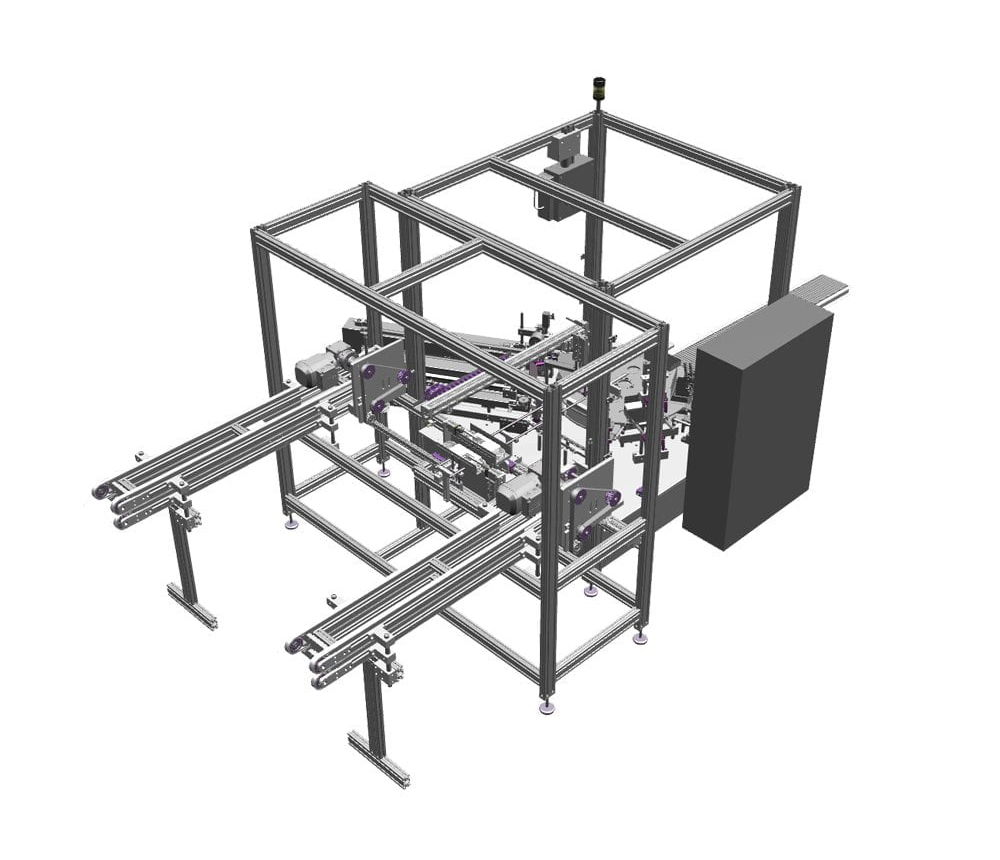

Automatic Folding Box packaging

The folding box full automated packaging unit consisting of 6 stations. The produced masks will be carried out of the two ultrasonic welding stations single by single to the stacking unit of the packaging machine via conveyor belt systems. The folding carton are fed in the machine by a magazine and erected.

After stacking the masks from the two feeding units the stacks are transported central above the cartons and fed in by product funnel. Previous closing the ear bands are again pushed into the carton and the carton are closed and as on option printed on the front. The closed folding cartons are pushed out to a roller conveyor which acts as well as buffer.

Accessibility to the ear band refilling by stairs beside module 30.

Technical data

- Machine output: max. 5 carton boxes per minute

- Roundtable with turntable diameter 800 mm and 6 process stations

- Folding box format: (closed - lxwxh): 200 x 100 x 100 mm (H min. 55mm)

- Folding cartons with automatic closing bottom and plug cap

- Control: Siemens S7 1500 and Touchpanel TP700

- Optional: Printing of carton front with Videojet M610

- CE certified