Automation technologies

PIA Automation solutions

Digitisation, with its almost infinite possibilities, has a positive effect on unlocking the innovative potential of researchers and product developers. Short lifetimes of trends and their continuous changes are the result. This has an impact on the product life cycle of all products and thus on production itself. Rising wage costs and quality requirements make the process along the entire production chain even more difficult. Flexibility is becoming more and more the credo of success through automation solutions.

- Automation solutions increase flexibility

- Automation is always individual

- Automation solutions from supply to delivery

Automation solutions increase flexibility

Automation solutions increase flexibility

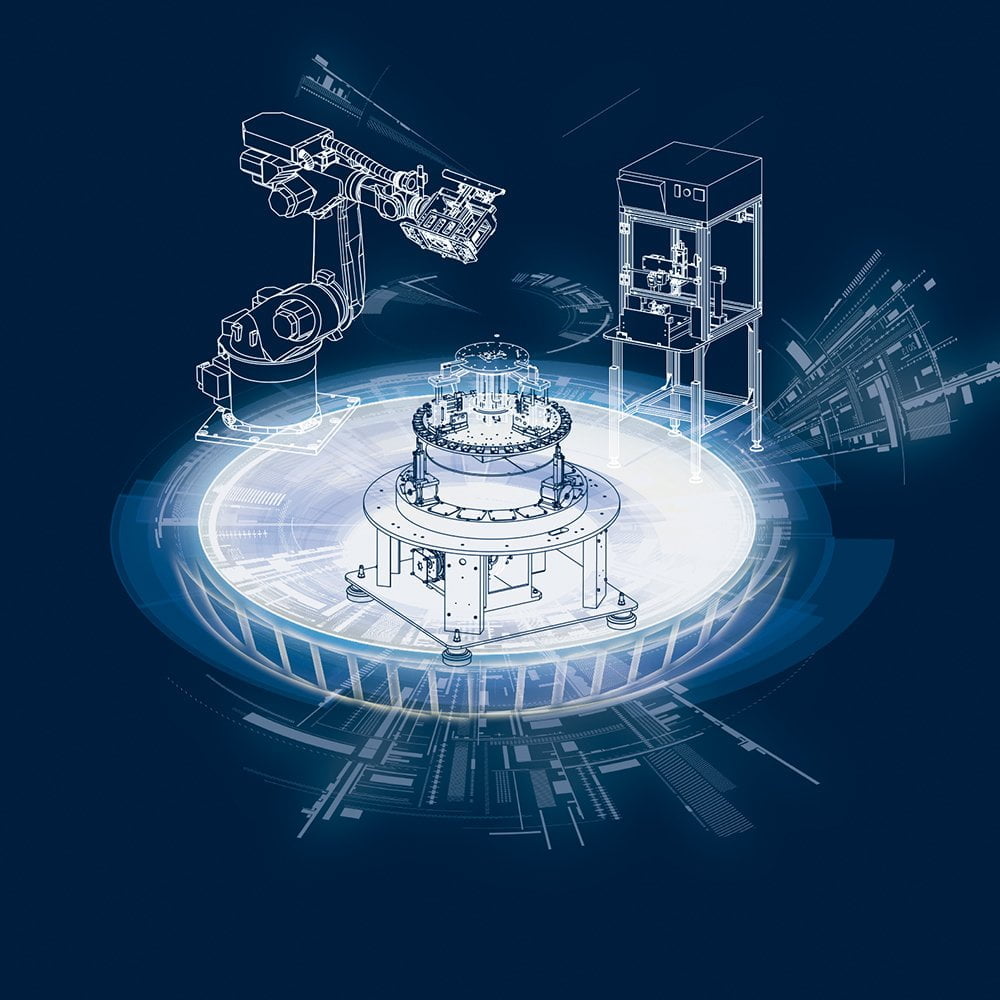

Modern automation solutions unite the virtual and real world and are synonymous with the flexible production of the future. Because there is no question that ever higher demands are being placed on production in terms of flexibility and efficiency. Modern automation solutions are the only answer to these requirements. The focus is not only on the production process itself. Rather, intelligent automation solutions consider the entire complex from the supply of raw materials to maintenance and delivery. In this context, the design of assembly and production machines plays an important role. In order to meet the increasing horizontal diversification of products, an efficient alignment of the investments to the various requirements is indispensable. This includes fast retooling as well as economic changeover between small and large quantities.

Automation is always individual

Automation is always individual

The individual degree of automation in the company depends on various influencing factors. A wide variety of solutions are used. Especially the human-robot collaboration (MRK) is gaining more and more acceptance in assembly lines. Here, the human being often takes on a monitoring function, while the machine performs specially defined tasks. This form of cooperation can be highly individualized and ranges from the pure control function of man to intensive cooperation between worker and machine. Adapted to the requirements of the company, efficiency and general economic efficiency of the production process increase significantly.

Automation solutions from supply to delivery

Automation solutions from supply to delivery

Industry 4.0 stands for the automation solution from raw material delivery to delivery and networked, and in some cases even cross-acceptance, software-supported automated communication. A vision that has meanwhile become reality through the merging of the virtual and real world. Above all, the further development of sensors and corresponding software solutions make an important contribution to progressive automation. Production machines communicate with the preceding stages and request required materials or workpieces that are automatically supplied by robots. Numerous sensors continuously collect data as part of predictive maintenance and supply it to processing systems, while production or assembly output stages additionally communicate with the storage systems.

In this context, predictive maintenance in particular is becoming increasingly important in the context of automation solutions. After all, this view of the future of production plants prevents expensive plant downtimes and repairs by reacting quickly and optimizes the planning of maintenance measures.

A TARGETED INCREASE IN PROFITABILITY - WITH PROVEN PIA TECHNIC

TECHNICAL PACKAGES

We offer targeted optimization packages with which existing production facilities can be selectively upgraded or converted to enhance their performance.

The following aspects are fundamental for our project philosophy

- Precision in function and construction

- Maximum process reliability

- Ergonomic operating concepts

- High-quality workmanship

PIA clictec® Systems

With clictec®, PIA offers a system which enables standardized holding fixtures to be used in workstations, resulting in a quick and flexible conversion of the automatic assembly machine. Full modularity and changeover of the workpiece holding fixtures, grippers, handling units and stations – all with just one click.

- Fast conversion of holding fixtures, stations, handling and feeding assemblies all done by “clicking”

- Cost-effective multiple use of the automation solution

- Maximum flexibility in the production of small or fast-changeover series

Cam control

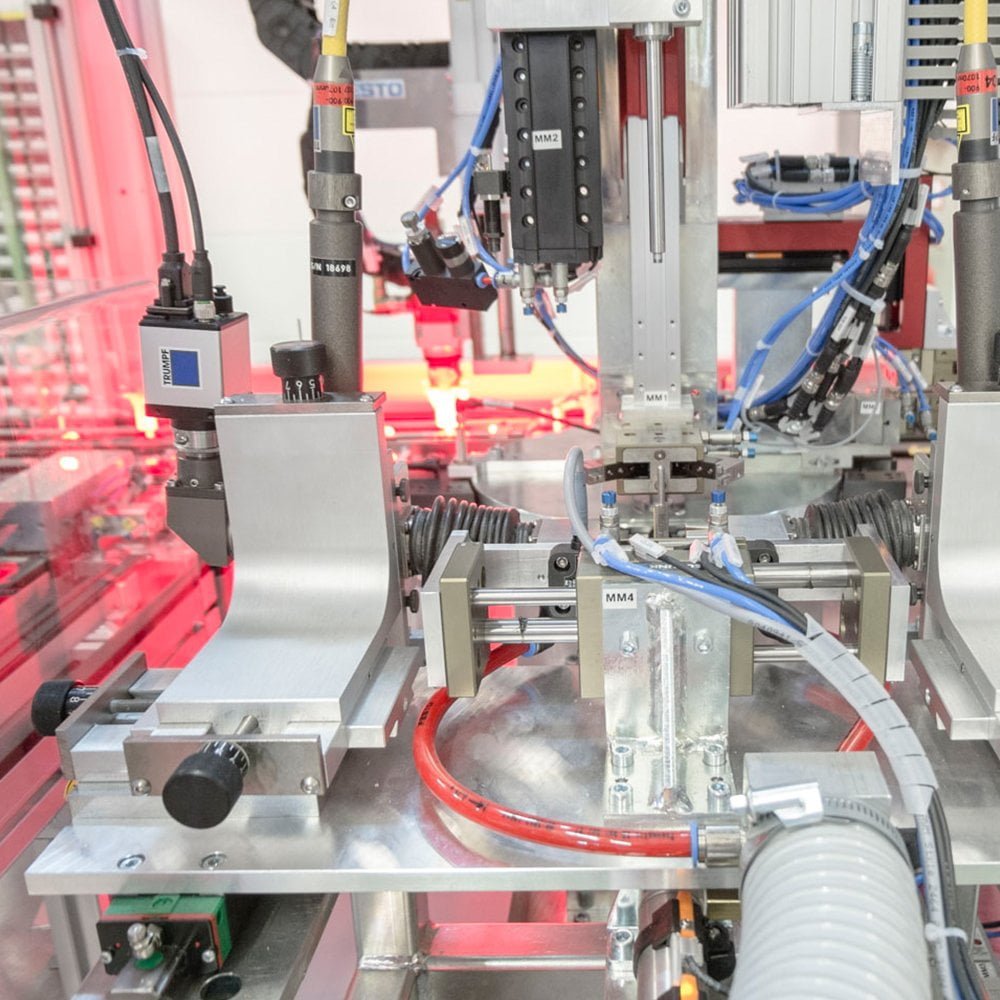

PIA has specialized in high-speed cam-controlled assembly lines for 40 years. This technology was always considered obsolete and outdated. When combined with modern drive technology, however, the result is innovative, extremely flexible and highly efficient assembly and testing facilities.

Cam controls are used for fast and intersecting motion sequences in all industries.

Cycle speeds of up to 500 cycles/min with simple processing or over 2,000 cycles/min with parallel processing can be achieved.

PIA cam controls can be found in various facility concepts. They are characterized by long service lives and a very high technical availability. The reason for this is the elimination of unnecessary components such as sensors, actuators and shock absorbers.