FFP2-masks - made by PIA equipment

Since the beginning of this week, the mask requirement has been tightened in Bavaria. N95/FFP2 masks must be worn in public transport and in retail outlets. These particle-filtering half masks (FFP: "Filtering Face Piece") are part of the personal protective equipment and protect against particles, droplets and aerosols. And not only the wearers, but also the person in front of them. This and the higher filtering performance distinguish them significantly from commercially available mouth-nose protection.

The masks (without valve) filter the inhaled and also the exhaled air over the mask surface and therefore provide both self and external protection. The mask design varies, there are pre-shaped variants, dome-shaped or foldable ("coffee filter shape"). It is important that the mask fits tightly against the face in order to develop its filtering performance.

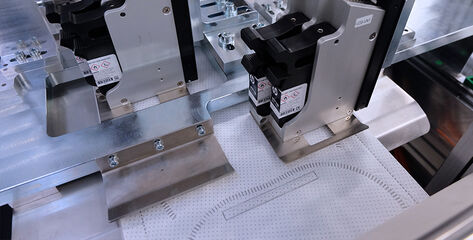

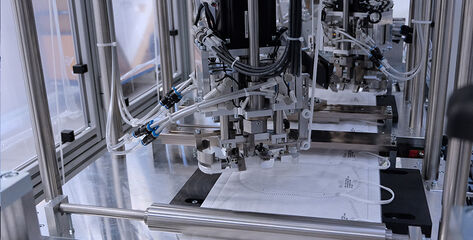

Demand for N95/FFP2 masks has risen sharply, especially for products certified and manufactured in Europe. PIA Automation Amberg has been working intensively on the automation of mask production since the beginning of the pandemic and has developed systems for the production of N95/FFP2 masks in addition to systems for the production of mouth-nose protection. The machines are suitable to process different contours of N95/FFP masks, to realize variants with ear or headbands and individual printing (company logo and certification number).

The production process includes coil feeding of nonwovens, nose wire feeding and positioning, ultrasonic roll welding, ear or headband feeding with welding on, mask folding, punching, waste ejection and mask output into box. The whole production line adopts digital communication, can provide data acquisition, production analysis and traceability, and user-friendly interface. The cycle time of this machine is up to 40 parts/min.

“With the N95/FFP2 production systems, PIA consistently continues on the path of making the automatic production of masks safer and more reliable through German engineering. The protection of health does not allow any compromises here.” Johannes Strasser, Head of Sales, PIA Automation Amberg GmbH

Further information can be found in the Case Study.