Automation solutions

Cable processing

There are not many industries and branches of industry that can do without pre-assembled cables in their production. They are particularly in demand in the fields of electrical and power engineering as well as in machine and control cabinet construction, which we take into account with our solutions.

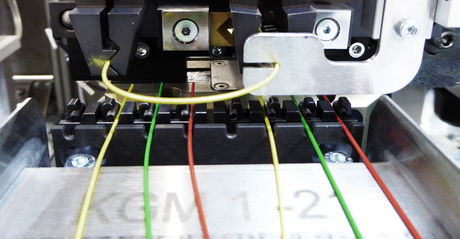

Because with the modern PIA cable processing lines, which are characterized by high efficiency and flexibility, we enable fast and precise processing of different cable types and sizes.

Such a line streamlines the production process and reduces overall costs.

EXPERIENCE COUNTS HERE

PROCESSES

- Feeding cable(s)

- Stripping

- Align cable(s)

- Stripping

- Install seal

- Zero cut

- Crimping

- Compacting

- Resistance welding

- Soldering (wire soldering, laser soldering)

- Connector assembly

- Switch assembly

- Camera test stations for monitoring and measurement

- EOL-inspections

- Marking, labeling, laser marking

DOWNLOAD

OUR PORTFOLIO FOR CABLE PROCESSING

Our machines for cable processing are capable of precisely cutting to length and stripping multi-core and shielded cables, stranded wires or flat ribbon and coaxial cables. They cover a wide range of wire diameters and cross-sections. The same applies to sheathed cables, crimp, slice, solder and weld connections.

Automation with solutions from PIA allows high productivity in many different applications. Nevertheless, our systems are easy to program and operate. Many functions can be pre-defined to simplify daily set-up and allow for diverse machining. Our design principles also ensure seamless integration into your manufacturing processes.

EXTENSIVE EQUIPMENT AND LONG SERVICE LIFE

The equipment - some of which is optional - naturally includes the appropriate knives, a straightener for all cables and strands for trouble-free and problem-free feeding, a material end stop, a deposit tray for orderly storage of the finished cables, and sufficient interfaces for peripheral devices and connection to the company IT infrastructure. Design and construction are robust enough to ensure long life and operation of our cable processing systems.

CONSULTATION

The choice of the right wire processing line depends on the specific requirements of each industrial sector. It is important to choose a line that meets individual needs while providing high quality and reliability.

Active consultation about our automated wire processing systems is a matter of course at PIA. Contact us and tell us about your task. Every single project is important to us and helps us to improve our products and thus their customer benefit in the long term.

CABLE PROCESSING LINES FROM PIA AUTOMATION

ADVANTAGES

- Customized special solutions for high cycle rates 30 parts/min

- Cable lengths from 120mm

- WPC transport system

- Cable routing on one side

- Optimal accessibility

- Can be combined with assembly tasks

Questions?

Get in touch with us

You can quickly reach your contact person for the automated production of commerical products here: