PIA Automation solutions

Fully automatic assembly systems

Assembly is usually the last step in the production of industrial goods and merchandise. Their share of the total production time is between 15 and 70 %, depending on the industry and the workpiece. It must also be taken into account that modern assembly not only has to be suitable for large quantities and long production periods, but is also characterized in many industries by an ever shorter product life cycle and a higher number of model variants. Fully automatic assembly systems today must be flexible, allow permanent monitoring and control and have a high process speed.

Based on these requirements, the need for rationalisation in the development and design of assembly systems becomes clear, for example to ensure the cost-effectiveness of assembly processes at high-wage locations. For both modern and future systems, it is increasingly important to move away from a product-oriented structure and move towards more technologically advanced systems. Modern assembly systems should therefore be able to adapt to changing production conditions, analogous to other machining processes in production, instead of just being rigidly aligned to a single process. This means that even small batches can be processed economically during changing assembly processes.

Higher productivity, lower operating costs - with PIA automation solutions

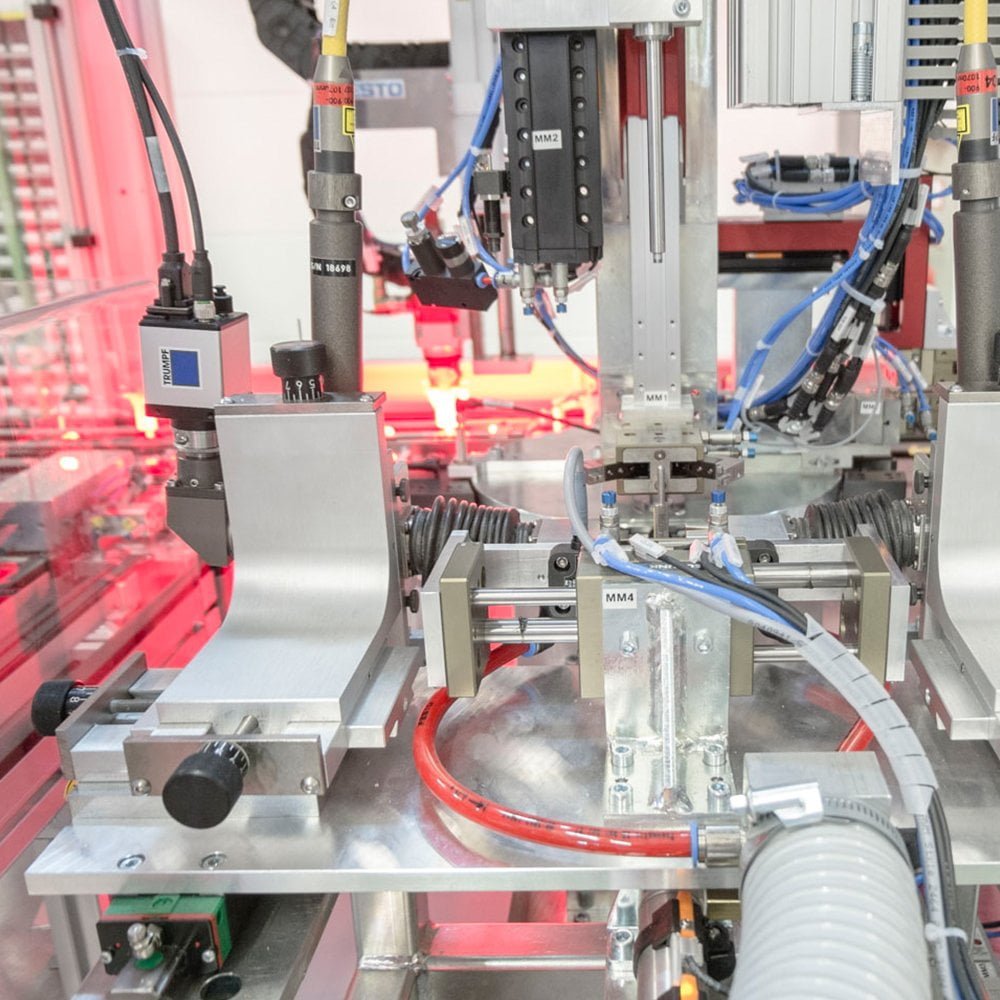

PIA's assembly and testing systems are designed, planned and implemented with the highest possible degree of automation in mind. This concerns the feeding of the individual components and assemblies, the integration of the necessary assembly steps through to the packaging of the finished assembled goods. This enables us to achieve a high output with short cycle times. With the help of our effective assembly systems, we enable our customers to significantly reduce their personnel costs and eliminate the need for human labour in certain production lines.

Another advantage of automated assembly is the exact reproducibility of the individual work steps. An integrated sensor technology ensures the targeted control of the processes. For effective quality control, the entire assembly process is permanently monitored. The data determined can be saved for complete documentation. In addition, our fully automatic assembly systems can be connected to accompanying or higher-level MES systems if required; the components are handled by AGV systems.

Stay flexible and conserve your resources

With our intelligent assembly systems, we ensure that the manufacture of your products remains economical and flexible, while at the same time conserving resources. We manufacture fully automatic systems for the most diverse work steps with which your components and assemblies are assembled into finished products. We always make sure that our systems are integrated into your production processes and linked to them in such a way that they offer maximum efficiency and that your investments pay for themselves as quickly as possible.

If you would like more details about our fully automatic assembly systems, please do not hesitate to contact us. We will be happy to advise you in detail.