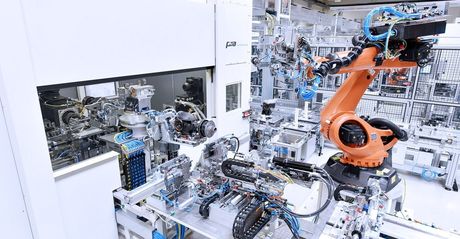

Automation solutions

Measuring and testing systems

Quality control and quality assurance are elementary components of any production process in order to keep the desired properties of a product continuously at the same level. Before a product leaves your company, it must be ensured that it meets all the requirements and services theoretically attributed to it in practice. Otherwise you can expect complaints or - in the worst case - even the loss of a customer.

In some industries a simple visual inspection by employees is sufficient. However, if complex technical parts or assemblies are involved, suitable measuring and testing instruments must be used which take into account and test all decisive parameters. If the measurement and testing is fully automatic, you increase your throughput rate and increase the production speed considerably.

PIA instruments measure any physical quantity

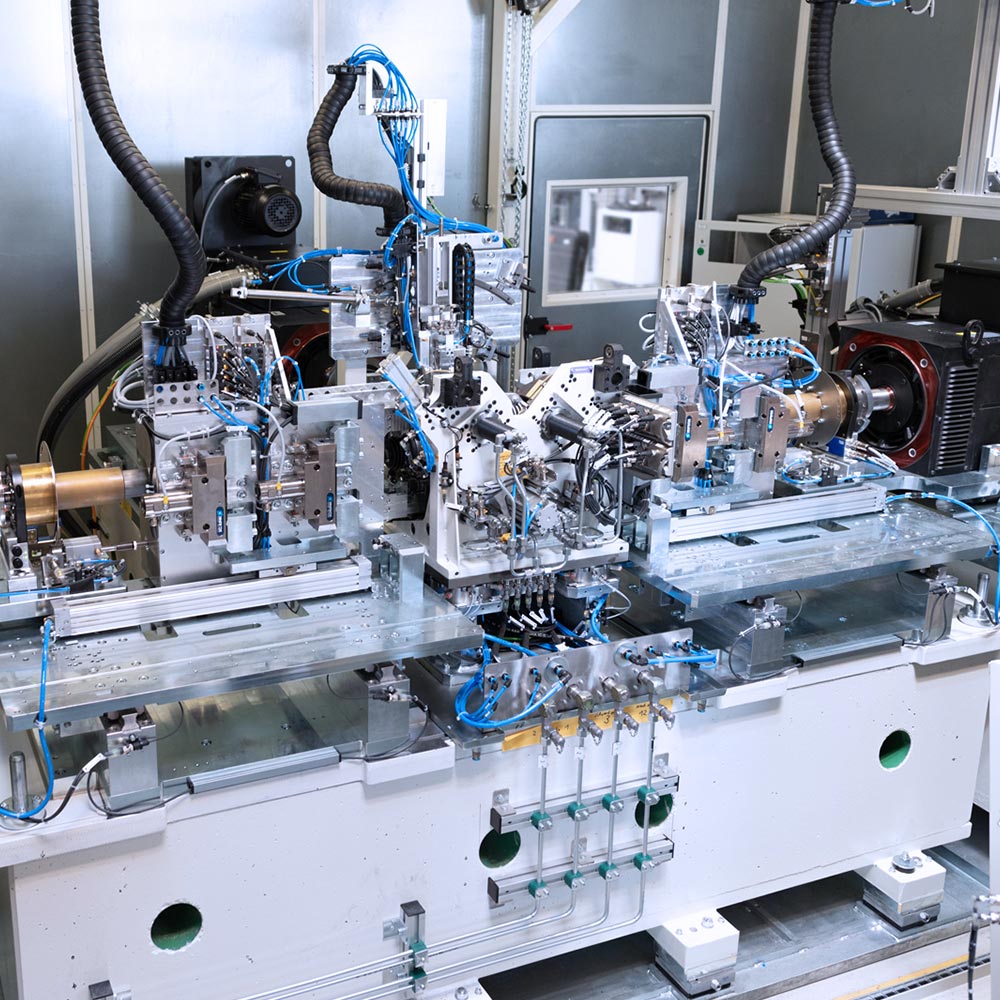

PIA has many years of experience and comprehensive expertise and is therefore in a position to design measuring and testing systems for any physical quantity. Whether it is a simple visual inspection or complex tasks such as measuring torques, determining force-displacement characteristics, haptic and acoustic tests, image processing, structure-borne noise and leak tests or the end-of-line test in a fully automatic test cell - our automated systems solve every task precisely, reliably and in the shortest time.

Everything from a single source

The conception and planning, the construction and detailed preliminary tests belong to our natural achievements in this segment, just like the supply and assembly of all mechanical and electronic components, the programming and start-up - in short: PIA supplies you your measuring and testing systems completely from a hand. You do not need to call in any other manufacturers or service providers.

Each of our measuring instruments can be connected to your IT via integrated interfaces in order to read and evaluate the collected data, so that you can react immediately in problematic situations and create documentation on the results.

Would you like to learn more about our automated measuring and testing systems? Then simply contact us without obligation. We look forward to your challenge!