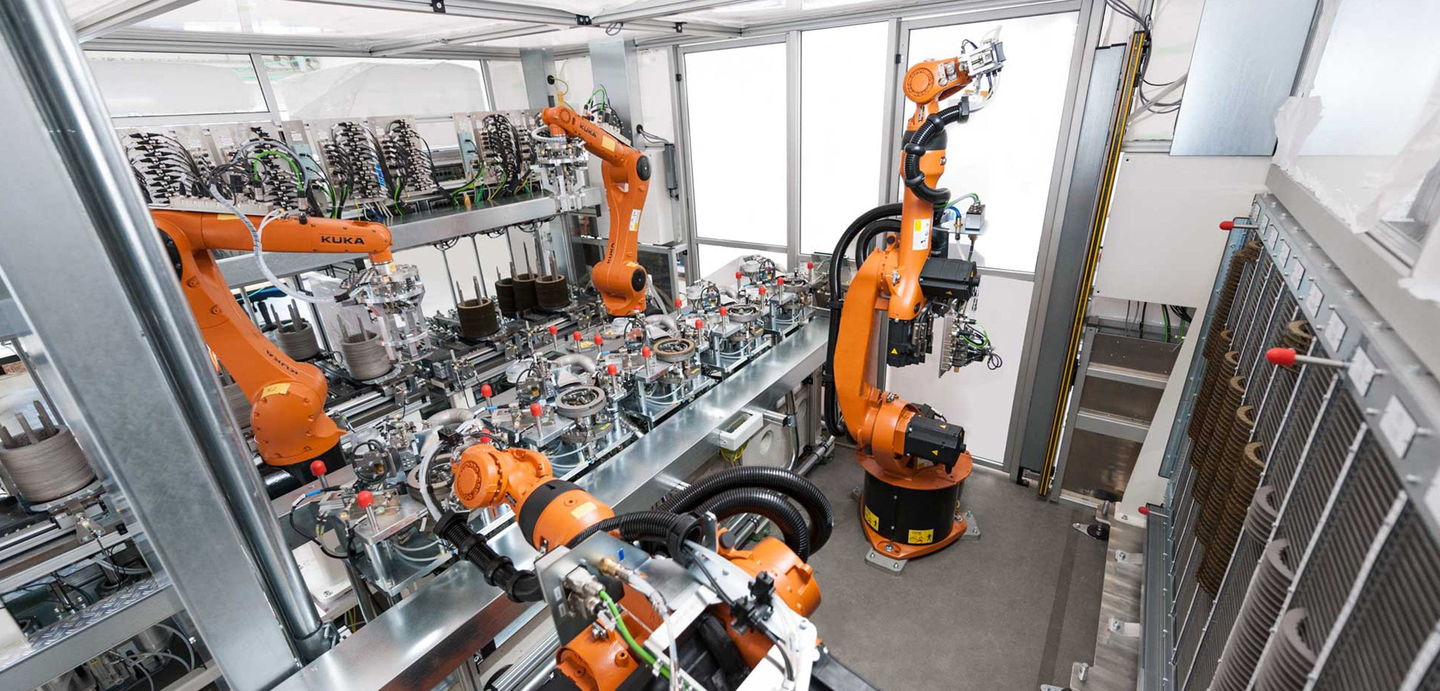

Case Study: Powertrain

Plate packing line system for dual clutches

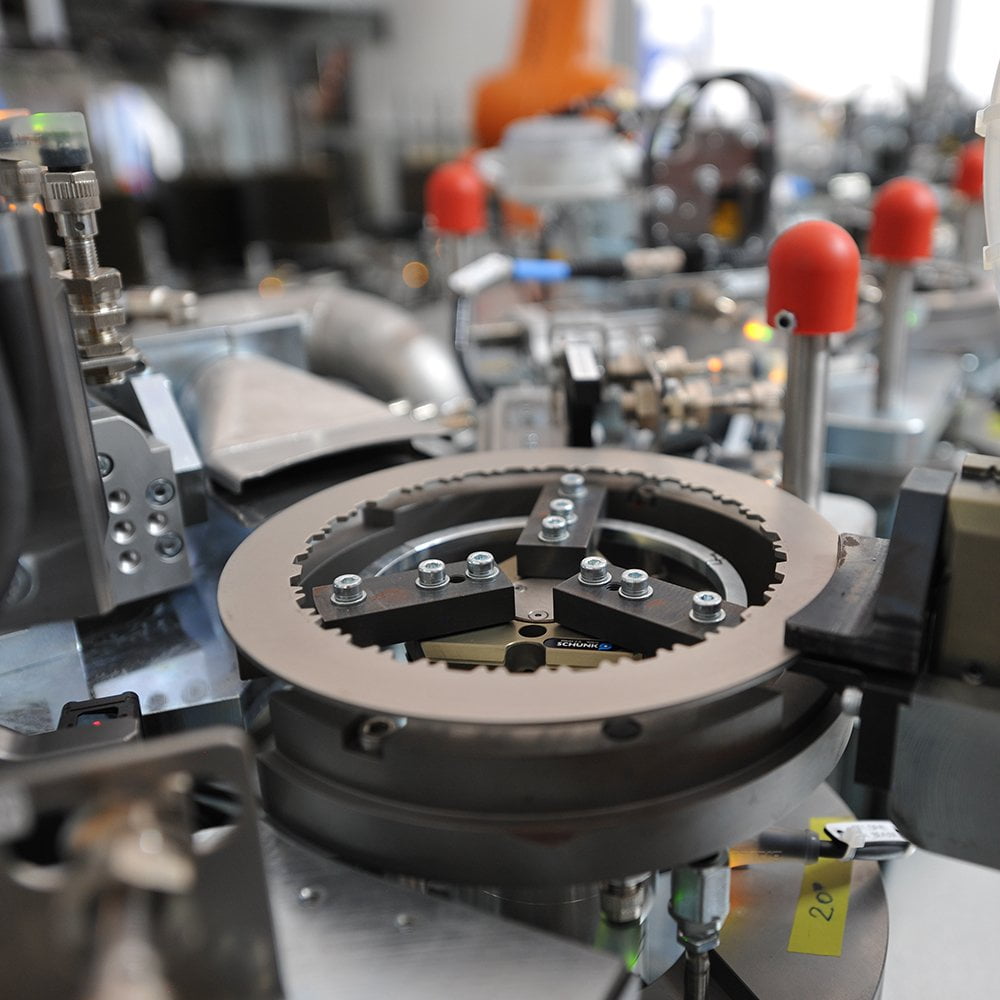

In the case of the clutch packs for a dual clutch, the deviations of the friction and clutch plates are optimally equalized.

Precision is key here: The thicknesses of the plates are measured and classified with a high degree of accuracy. The clutch pack is then sized in such a way that the thickness deviations are optimally evened out and the result is checked under a preload of the package.

- Cycle time 40 seconds

- 2 product types

- 9 robots

- Automatic plate feed

- Cleaning station

- Plate storage for classification

- Measuring system for final inspection of the clutch plates