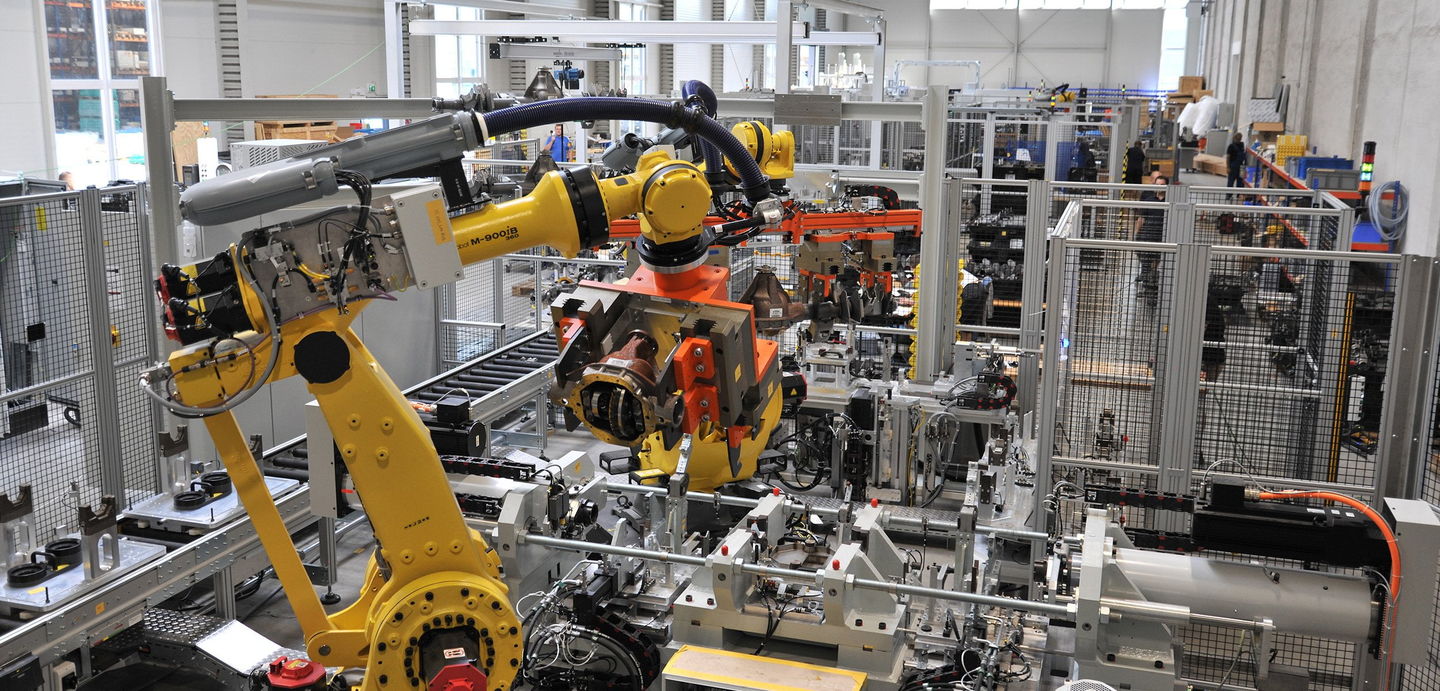

Case Study: Powertrain

Rear axle transfer transmission with rigid axles

The assembly line system includes all measuring and assembly processes for a rear axle transmission, plus additional modules for assembling the axle tubes, side shafts and wheel bearings with the brake modules.

Due to the size and weight of the component, and the variants to be produced plus future versions, the workpiece carriers are equipped with exchangeable holders. Due to the high demands placed on the positioning accuracy of the vehicle assembly boreholes, these are inserted into the mounting brackets by means of a laser cutting process after the axle has been mounted.

- Cycle time 70 seconds

- 24 assembly stations

- Assembly layout in O-shape

- External material positioning

- Laser cutting process

- ABS functions test