END-OF-LINE-TESTER of PIA AUTOMATION

flexible test systems

For many years now, electronics have been used more and more in numerous products.

End-of-line tests are therefore essential for every manufacturer to minimize risks and ensure the safety and satisfaction of users. To ensure test coverage at the highest possible throughput, you need a flexible test solution from PIA Automation.

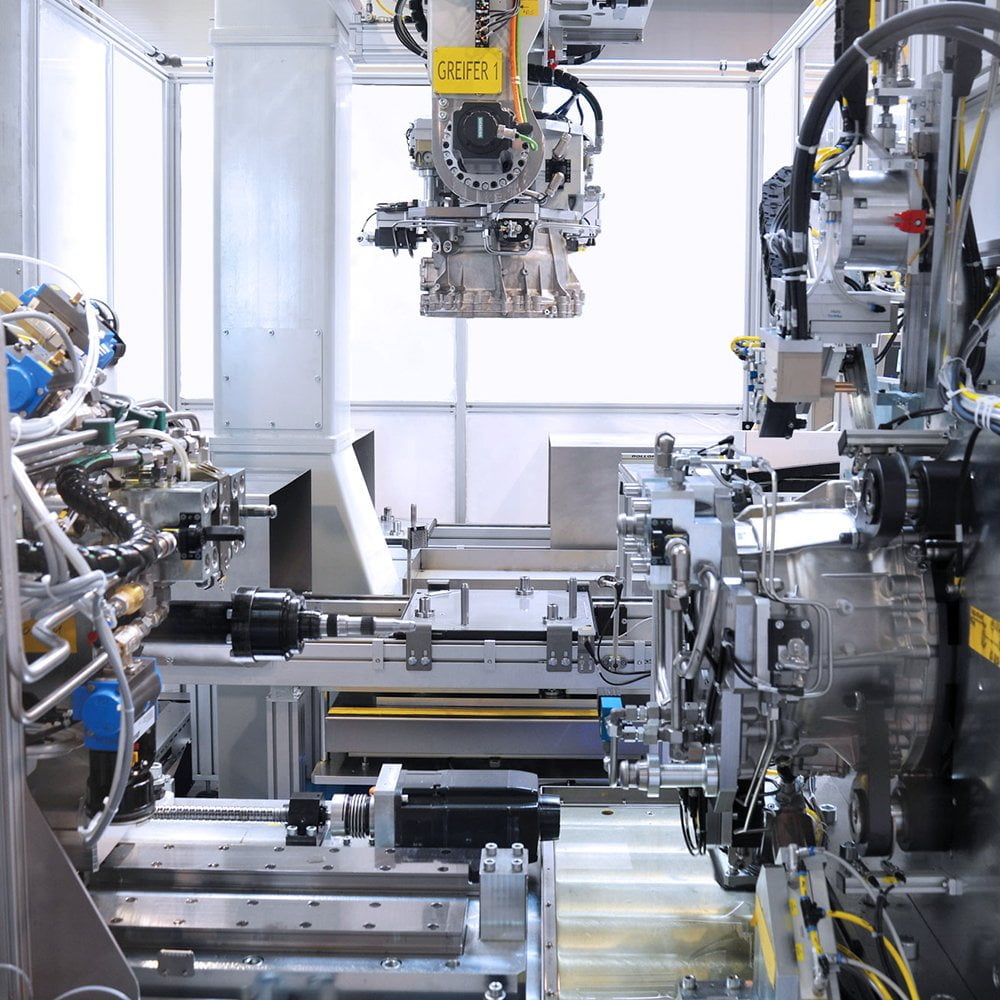

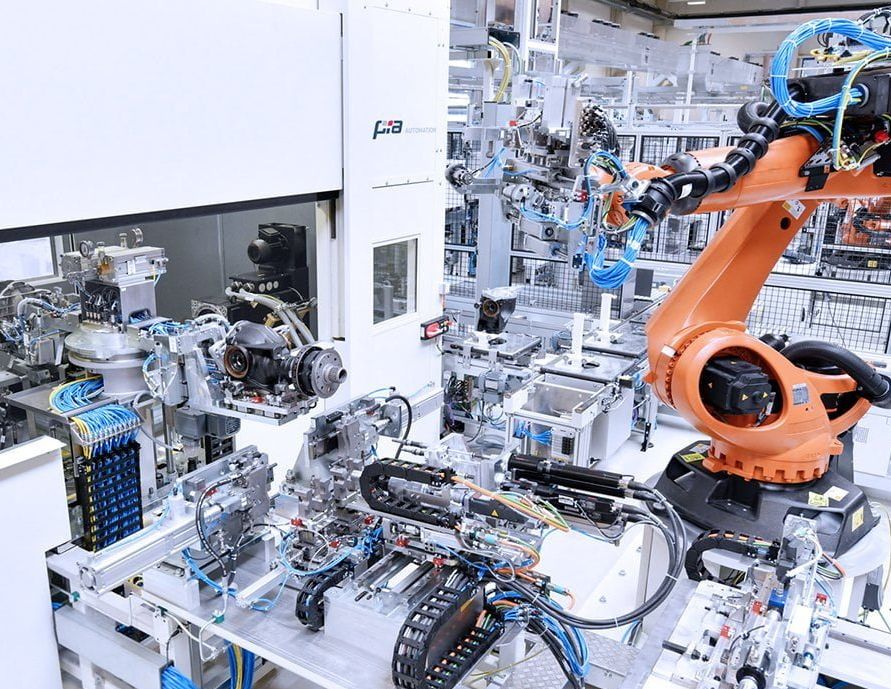

Test systems from PIA set high standards in terms of precision and high quality. The portfolio ranges from complete end-of-line test fields to in-line testers integrated into the assembly process. Independent of fully automated test concepts with low cycle times, PIA's product and service range also covers the development and manufacture of audit test benches with maximum product flexibility.

Questions?

Get in touch with us

Are you interested in test systems from PIA? Do you have questions about our various EOL testers?

Then please contact us!

We are gladly at your disposal.

test stations

Advantages

- Wide range of applications (stand-alone, inline, interlinked test fields)

- Flexible loading systems (manual, handling, robot, transfer) for scalable expansion stages

- Optimal interaction with our industry 4.0 solutions

- Development, production, support and know-how from one source (one-stop shopping)

- Experience in numerous test procedures for more than 50 years

- Single to multiple checks (scalability)

- Testing in mounting position

- High flexibility and availability

- Low space requirement

- Short loading times

- Easy to use

- Freely programmable test sequence

- Solutions for data storage of quality data and for production data acquisition

- Reuse by changing the test tools

- Possibility of upgrading to future mechatronics

FAST, FLEXIBLE AND AUTOMATED

IMPLEMENTED TESTING PROCESSES

- Flashing of specific test or final control unit software

- Static and dynamic electrical tests (e.g. insulation and resistance tests, voltage, current, ...)

- Counter measurement and calibration (e.g. torque transmission of couplings, resolver offset, currents, ...)

- functional tests (parking lock, disconnect unit, differential lock, ...) and their characteristics

- Measurement of structure-borne noise (NVH) and airborne noise

- Rotational Acceleration Test

- Performance check

- Simulation of electrical components (e.g. battery, motor, resolver and inverter)

- Simulation of the vehicle communication bus (rest bus simulation)

- Structure-borne sound test

- Camera inspection

- Leak test

- Ultrasonic testing

- Measurement of circumferential backlash

FULL SERVICE

EVERYTHING FROM ONE SOURCE

The conception and planning, the design and detailed preliminary tests are part of our self-evident services in this segment, as well as the provision and assembly of all mechanical and electronic components, programming and commissioning - in short:

PIA delivers your measuring and testing systems completely from one source. You do not need to call in any other manufacturers or service providers.

Via integrated interfaces, each of our measuring devices can be connected to your IT to read and evaluate the collected data, so that you can react immediately in problematic situations and create documentation of the results.

PIA Benefits

HIGH SPEED MEASUREMENT TECHNOLOGY

The use of industry-proven measurement technology from various manufacturers such as National Instruments, HBM or Beckhoff, offers a highly accurate and channel-spanning time-synchronous measurement (< 1μs) at sampling rates up to 1M samples/s.

PIA Benefits

VEHICLE COMMUNICATION

PIA relies on established products from Vector, such as the Compact IPC VN8900 with the CANoe software package, which can be integrated like all common vehicle bus systems (such as CAN, LIN or FlexRay). Finished OEM residual bus simulations, based on CANoe, can be integrated or updated with minimal effort. AUTOSARcompliant UDS functions such as Security Access, calibration routines, error memory functions or updates of the control unit software (flashing) are available as test steps.

PIA Benefits

CONFIGURABLE TEST PROCEDURES

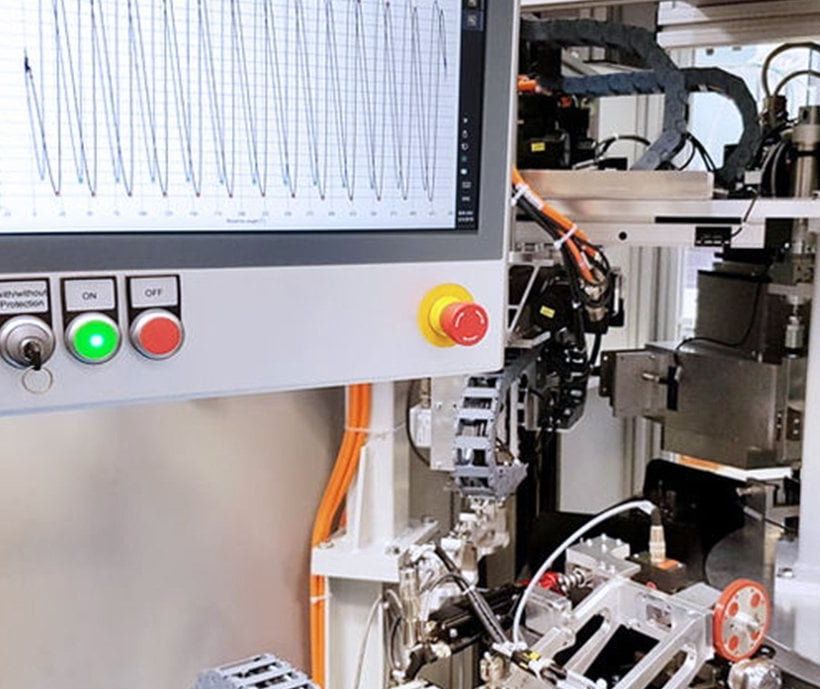

With National Instruments, our customers can test and create test sequences from a library with PIA’s assemble and parameterize function modules. The user-friendly interfaces are optimized for the use of test systems within production environments.

PIA Benefits

REPORTING AND ANALYSIS

National Instruments has expandable plug-ins for report generation, logging in databases and connection with other company-wide systems. The user interfaces of the PIA-EOL testers offer the operator both live displays for test results and signal characteristics, as well as functions for the analysis of historical measurement curves and event logs.