Case Study: Components

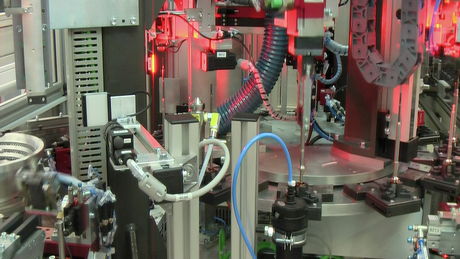

Fully automatic assembly line for the assembly and testing glow plugs

Production line consisting of pre-assembly module (2 Weiss rotary tables), press-in module (AGM12050), final assembly module (AGM16070), thermal testing system (linear unit), labeling and packaging module (Weiss rotary table). The components are interconnected by a workpiece carrier circulation system (2 sets: 1x production, 1x waiting position, automatic changeover). Setup is carried out exclusively by means of program specifications – for this purpose, more than 20 servo axes move automatically to other basic positions.

Processes

- Automatic parts feeding

- Assembly

- Type testing via line scan camera

- Greasing

- Annular gap test

- Test for swarf freedom

- Optical examination of the contours

- Linear measurements

- Pressing-in with monitoring of force and travel

- Crimping

- Temperature measurement (900°C) via infrared sensors

- Power consumption test

- Cooling of the components by means of water-cooled gripping jaws

- Concentricity check by means of image processing system

- Laser inscribing (Rofin-Sinar)

- Thread rewinding

- Packing in bags (IVECO pack)

- Traceability

- Host computer connection

Cycle rate

26 parts/minute = 2.3 seconds per part