Perfect displays thanks to optical bonding

Optical Bonding: So heißt das Verfahren, das beim Zusammenfügen von Display-Komponenten zum Einsatz kommt. PIA bietet Lösungen, die diesen komplexen Prozess automatisieren. Die PIA Lösungen fügen einzelne Komponenten wie Glasblende und Touch-Sensor exakt aufeinander – mit gleichbleibend hoher Qualität und in schneller Taktzeit.

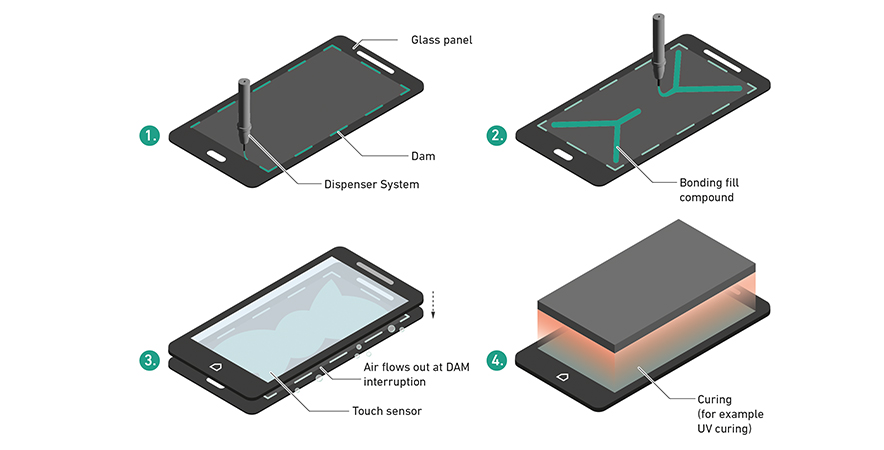

Optical bonding: This is the name of the process used to join display components. PIA offers solutions that automate this complex process. The PIA solutions join individual components such as glass panel and touch sensor with high precision, consistently high quality and in fast cycle times.

The control units bonded in this way are used in a wide variety of industries, in the automotive industry as well as in consumer electronics and household appliances. Capacitive systems, meaning touch screens that react very sensitively to touch and can be controlled with high precision, are increasingly in demand.

PIA Automation has already successfully developed and installed several such systems. They all master the highest form of optical bonding: liquid optical clear adhesive bonding (LOCA bonding). In this process, the so-called bonding fill compound is applied in between the individual components, which is then distributed over the entire surface between the components when they are joined together. The result is a robust composite that is protected from dust or moisture by the fill compound. In addition, displays bonded in this way offer excellent readability thanks to low reflections and can also be controlled precisely by the touch of a finger.

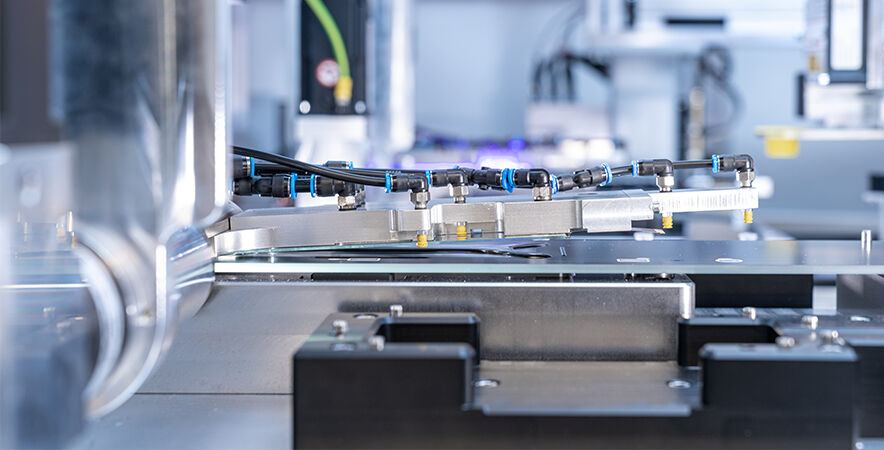

The PIA systems for LOCA bonding can be operated around the clock, and they work with absolute precision and high repeatability, forming the backbone of efficient display production.

Our technical article discusses the most common optical bonding processes, identifies differences between them and shows possible applications and potential for automated LOCA bonding processes.