Measurement system piaDynamics

Flexible, intuitive, Industry 4.0 ready

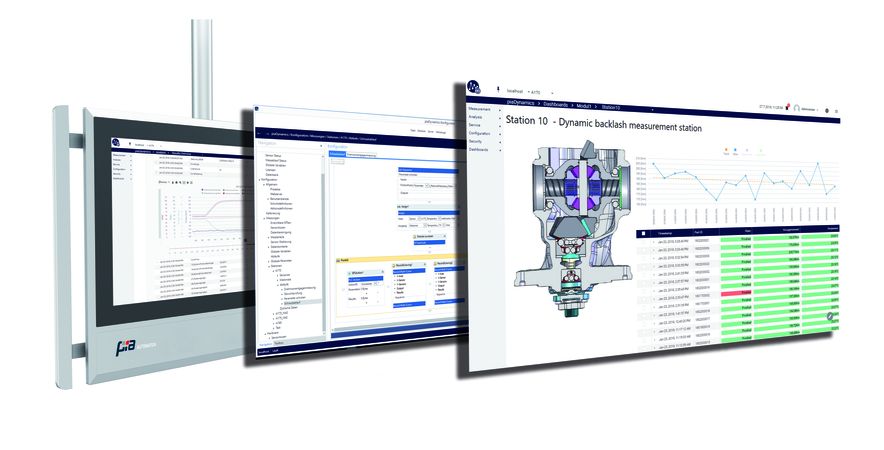

piaDynamics is a measurement computer system for production systems with a high level of automation. Its combination of intuitive software and flexible hardware sets it apart. Network options and the latest web technology make it ready for Industry 4.0.

piaDynamics is predestined for applications with high demands in terms of measuring accuracy, for example in the areas of automobile transmission and assembly. Because highly complex measurements play an important role in those areas, which not only require static measurements like individual paths, lengths, pressure or forces, but also measurement of dynamic processes, like the meshing of gears. One example is circumferential backlash measurement, which is used to test the alignment of teeth in a set of gears. It has a significant effect on the transfer of forces and acoustics in transmissions.

Flexible hardware, intuitive software

Unlike most competing products, the software is not limited to certain hardware components or expansion cards. That makes piaDynamics completely flexible in use, including with regard to the hardware used, which only has to meet certain minimum requirements. Further advantages of the PIA web application include its intuitive interface and simple menu, which is among other things, suitable for mobile end-user devices. The measurement data is presented for analysis and statistical evaluation in the form of numerous modern graphics, and the application can be used with touch screens.

Configuration instead of programming

Another unique selling point is the ability to configure the measurement computer, rather than programming it. A graphic editor offers prefabricated function blocks, which allow measurement technicians and quality managers to create and edit measurement sequences. That means knowledge of line programming is not required to use the measurement software. Instead any user can produce and adapt measurement sequences by simply using the configurator. It also means that piaDynamics does not actively intervene in controls. It simply communicates with the PLC by sending and receiving the appropriate values and commands for further processing.

Industry 4.0 thanks to intelligent networking

The option to network several measuring units with a single measurement computer also means that piaDynamics is Industry 4.0-ready. And it offers considerable savings in terms of the necessary investment in hardware. Networking means all processes throughout the entire system can be monitored. Numerous control circuits with individual measuring units can be set up throughout the system, and then analysed and adjusted from a single measurement computer. Because all the measuring units are networked, certain parameters can be changed over time to counter any changes in quality. Industry 4.0 is also reflected by the measurement system’s remote access options: The measurement computer and the results it generates can be accessed from anywhere using a mobile device with a browser. Other measurement systems are generally stationary and have to be operated on location, at the system. Remote access offers considerable time savings and a significantly greater level of convenience for users.

Numerous types of sensors and signals

In the past, piaDynamics was mainly used in the automobile industry, particularly in the areas of transmission and assembly. However, it is also highly suitable for many other industries with high levels of automation. A broad range of sensor types and signals are supported, including inductive probes, analogue inputs, counter inputs and sensor bridges (further sensor signals available on request). Whether in the planning process or at a later date: piaDynamics can be installed when a system is first set up or as a retrofit solution.