piaOptimum significantly improves OEE

In the ramp-up phase of a new assembly line, start-up difficulties, such as excessively high scrap rates or unstable cycle times, are not uncommon but causes must be detected and eliminated quickly. Using the piaOptimum software program, PIA accompanied the ramp-up phase of an electric motors production line at the Schweinfurt facility of the automotive supplier ZF. With the help of piaOptimum, sources of error could be identified in a targeted manner and the overall equipment effectiveness (OEE) was significantly increased.

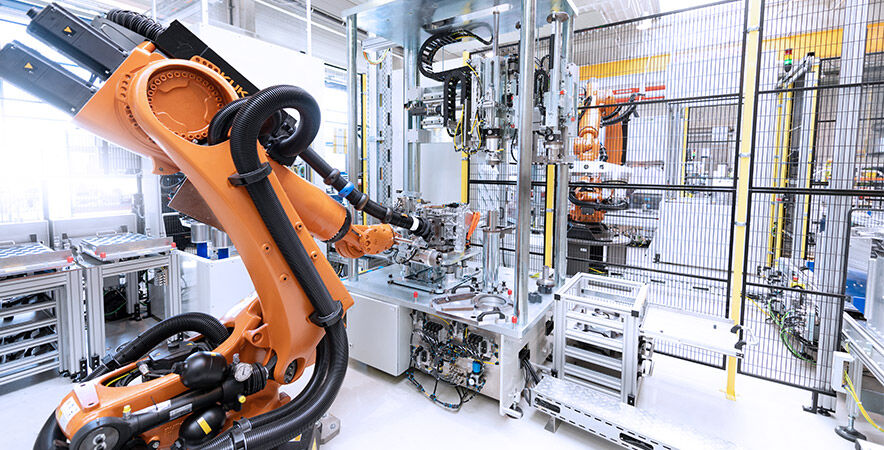

The operations between man and machine must always be thoroughly coordinated, especially in a case of complicated lines with several stations, including robot cells, automatic stations, but also manual stations. However, identifying the exact sources of interference is often difficult. Thanks to comprehensive data collecting, analysis, and processing, piaOptimum helps make the source of an issue visible.

With an interdisciplinary team of PIA experts and specialists from ZF, the entire line was scrutinized using piaOptimum. Michael Juwan, Global Expert PIA4.0 at PIA Automation Austria, describes the procedure: "With piaOptimum, which takes the most important data from the line and prepares it in a transparent and understandable way, errors could be clearly detected. We then evaluated them: Where are the problems and bottlenecks? When and why do they occur? What losses do they cause? Then they could be prioritized more easily and assigned to the right work team and processed." piaOptimum can record every secondary process at a station in a very detailed manner down to the partial cycle level to detect fluctuations and anomalies.

"The OEE was significantly increased at the end of the first optimization phase. In power runs under optimal conditions, an overall plant efficiency of almost 90 percent was achieved – this is already a satisfying value – and we will continue to optimize the plant and the processes accordingly," says Sebastian Krause, Manager Manufacturing and Engineering at ZF.

In our user report, you can read about the measures taken to stabilize processes and shorten cycle times as well as what data was provided by piaOptimum.