PIA’s intelligent software framework

The Software Engineering Department in Bad Neustadt has developed a designated software framework for the comfortable programming of so-called end-of-line (EOL) testing stations. Martin Kroenung (Department Head) tells us what this is all about and which advantages the customers have.

What is "PIA Smart.LV 2.0"?

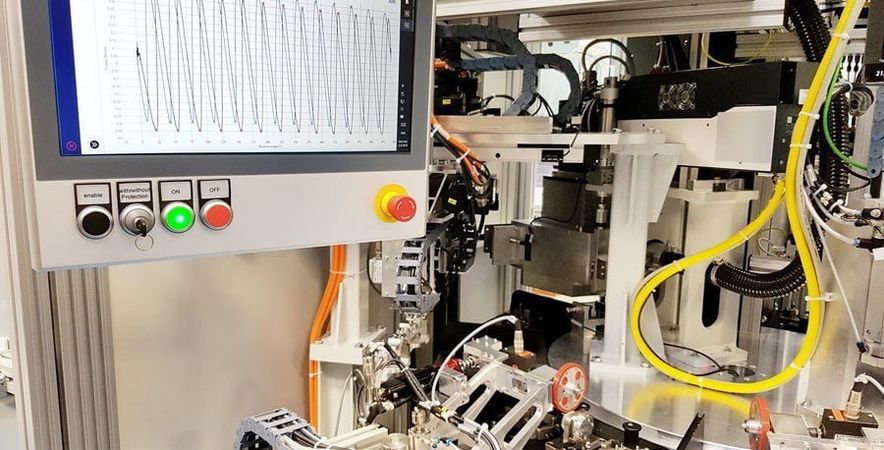

The name "Smart" stands for "intelligent" as well as for "software framework for measurement, automation, robotics and testing". LabVIEW (LV), produced by National Instruments, is a graphical programming language which is particularly strong when it comes to the integration and programming of measuring hardware. Since we have been programming EOL testing systems using LV for two decades we were able to gather lots of experience. This know-how has had a significant influence on the development of PIA Smart.LV 2.0. Our software framework consists of individual modules to control various hardware components which are dynamically loaded in an object-oriented manner at the programme runtime. Furthermore these modules can communicate with each other via so-called plug-ins. A text based sequencer will place the connections between LabVIEW modules. The individual objects are compiled of various levels, from the hardware to the HMI level (human-machine interface).

What are the benefits of PIA Smart.LV 2.0?

PIA Smart.LV 2.0 uses an industrial PC with Windows 10 as an operating system. The HMI always has the same look and feel. Thanks to the various object levels, flexible hardware component can now be changed or extended, fully depending on the application setting and customer requirements. Operation and programming remain the same, regardless of whether, for example, a linear drive from supplier A or supplier B is used. In addition, we are not bound to specific communication media and protocols. This reduces the programming effort. Especially in the field of EOL tests it’s all about gaining experience with new products or testing processes at several points. PIA Smart.LV 2.0 now allows the customer to change testing processes themselves. For basic process changes, the sequencer with step functionality, live display of the variables and live debug function is available.

Martin Kroenung (PIA Bad Neustadt)

"With PIA Smart.LV we are flexibly positioned for future technologies."

Can we expect to see additional features in the future?

Definitely, yes. In many cases, we already equip the system with a soft PLC. So far, however, we have only used these at the lowest level for digital inputs and outputs. Furthermore, we are constantly working with students on various topics such as connectivity to IIoT platforms and concepts regarding Industry 4.0 or interface solutions using OPC-UA.

PIA Smart.LV 2.0 and Industry 4.0: Does it match?

Very well actually! Thanks to increasing product complexity and requirements towards Industry 4.0, we are optimally prepared with a PC-based solution. For instance, we have only recently completed the first two universal robot testing cells for a customer’s laboratories. One cell is located in Germany, the other one in China, and both are linked. PIA Smart.LV 2.0 makes it possible to set up precise robot processes in Germany and to transfer them to the Chinese machine, all the way down to the robot’s controls. There, the process can be run directly for test purposes.