PIA Automation now also offers machines for FFP3/FFP2/N95

In addition to the already developed systems for disposable facemasks, standard machines are now also available for the specific filter masks.

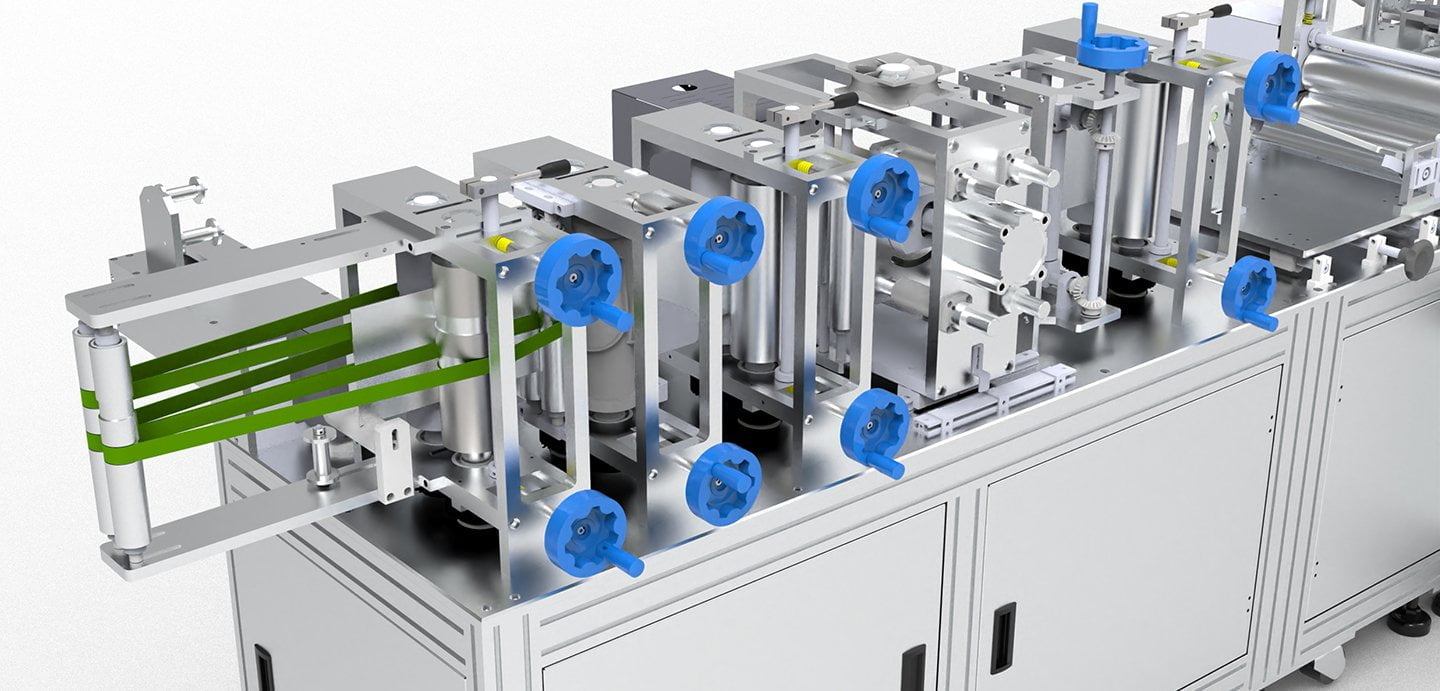

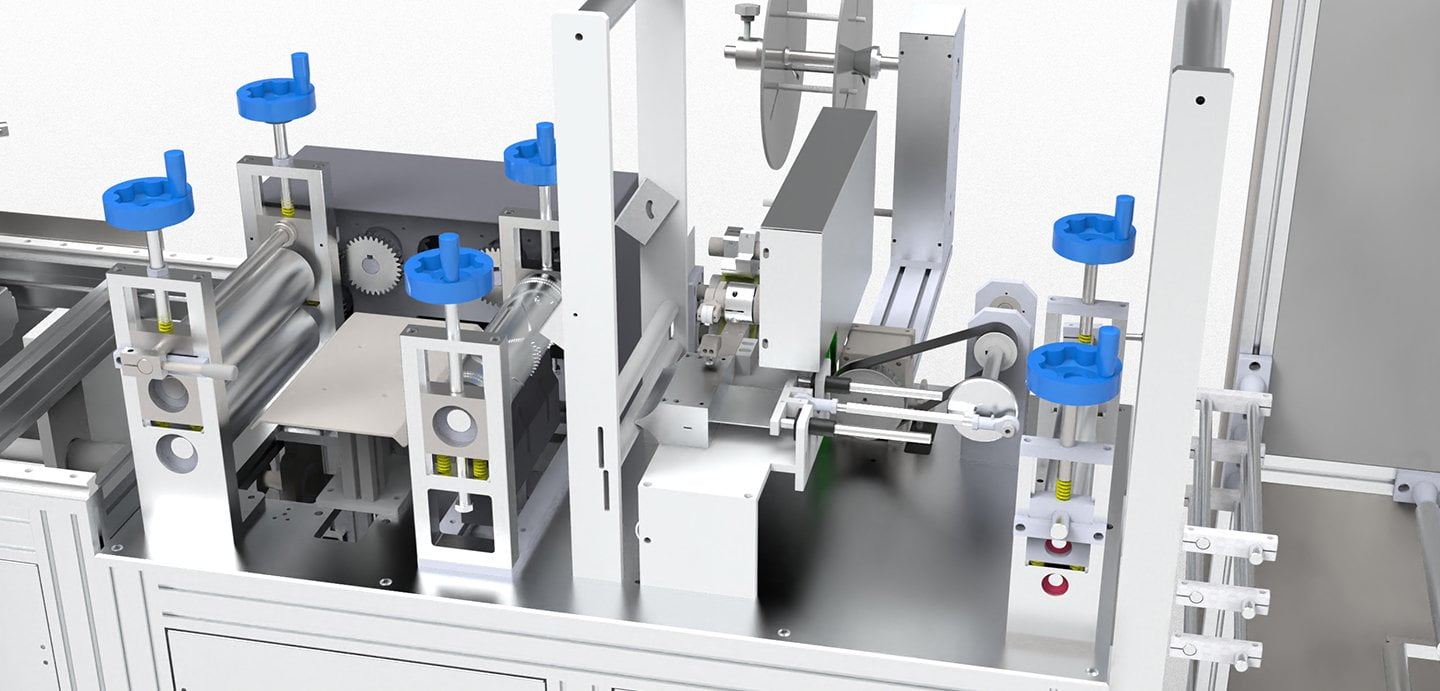

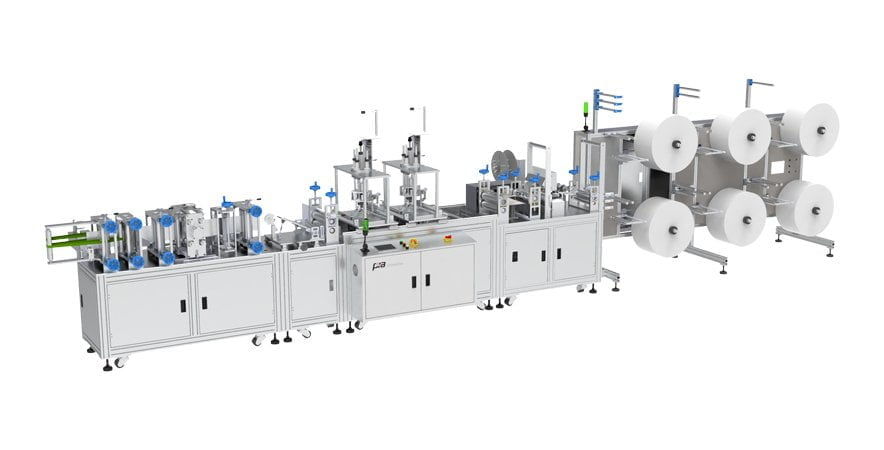

The manufacturing process includes coil feeding of the nonwovens, nose clip feeding as well as positioning, ultrasonic roll welding, earband feeding and welding, mask folding, punching, waste discharge and output of the masks into a box. The entire production line uses digital communication, can provide data acquisition, analysis and traceability of the production and a user-friendly interface. The cycle performance of this machine is up to 50 parts/min.

FFP3/FFP2/N95 masks consist of nonwoven, which is folded in different layers to meet different protection requirements. "Polypropylene nonwovens are frequently used in the manufacture of medical protective clothing," says Lothar Mehren, head of the Medical Division at the Amberg site. In addition, they also consist of two elastic bands and an adjustable nose clip.

Such masks are used for self-protection and the protection of people in the immediate vicinity who could be infected by contagious droplet transmissions without a mask.

At PIA Automation, up to 120 employees across all departments are involved in the development, sales, procurement and manufacture of the mask machines, said Managing Director André Vales. The regular production runs with the existing teams within the given time schedule. All employees work very responsibly and accept many hours of overtime as well as a temporary 3-shift operation for the duration of the "hot production phase" in order to enable the delivery of urgently needed equipment in the shortest possible time".

CASE STUDY FFP3/FFP2/N95 MASK PRODUCTION