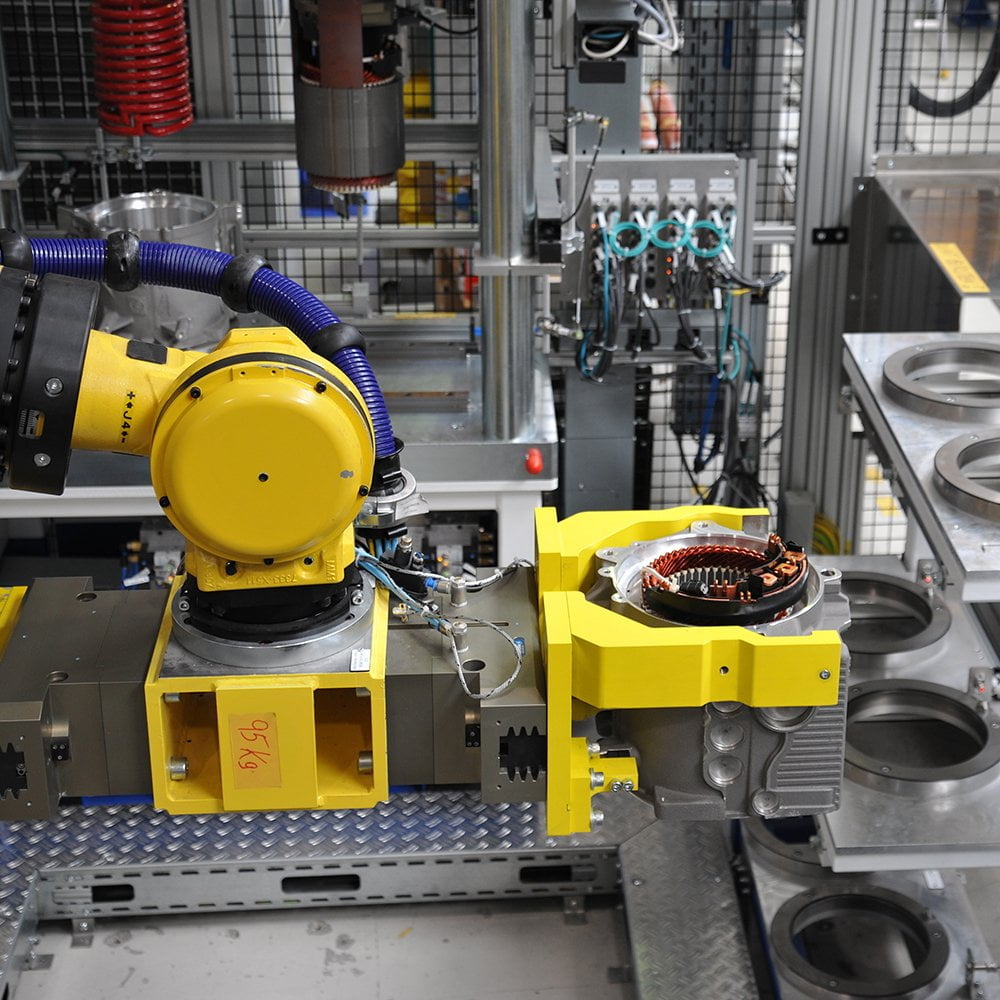

Case Study: eMobility

Assembly and testing line system for e-drive modules

The electrical components of e-drive modules create new requirements for assembly and testing processes.

In addition to the well-known assembly processes of a transmission, the additional electrical components mean that special requirements for ESD protection, high magnetic forces and the installation of sensitive electronic components and their testing must also be fulfilled.

For transport, the e-drive is mounted on a subcarrier, which enables a wide variety of assembly configurations to be handled, including exact clamping during the EOL test. Due to the high cycle time and the flexible number of workers, a walk-in low-floor transfer system for component transport and stations with more extensive work contents was implemented in order to provide the customer with an economical production facility.

- Cycle time approx. 4 minutes

- Flexible number of operators

- Low-floor transport system

- Subcarrier for assembly and testing

- High product weight

- High-voltage testing of control unit flashing