Case Study: Consumer goods

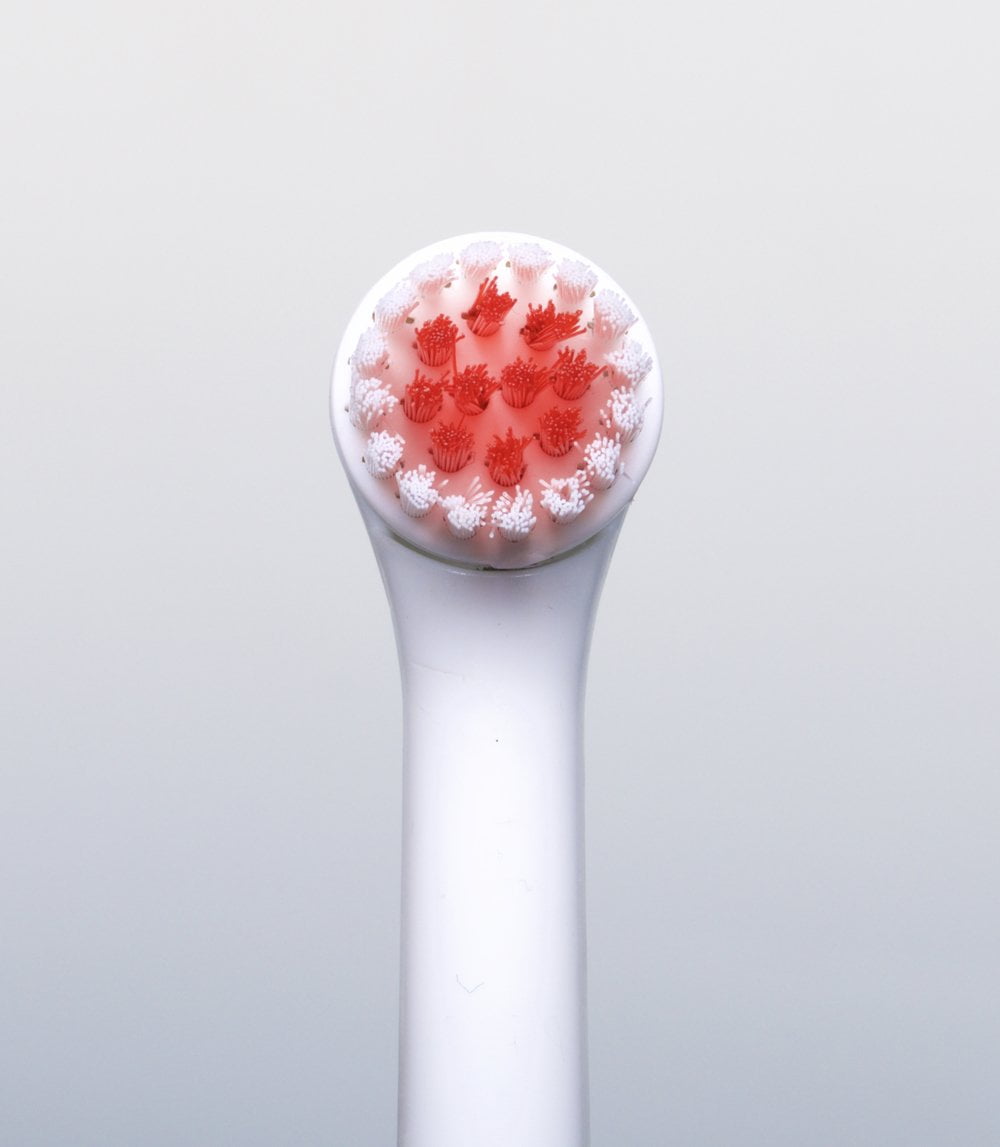

Assembly line system for toothbrush heads

Fully automatic assembly line system for brush heads with 3 variants. Assembly is done by means of a cam-controlled rotary table system (PIA EGM) with 22 assembly and testing stations.

Processes:

- Minimal mechanical setup

- Automatic parts feeding

- Assembly of 5 components

- Process control

- Optical inspection

- Mechanical testing

Cycle time: 50 parts/minute