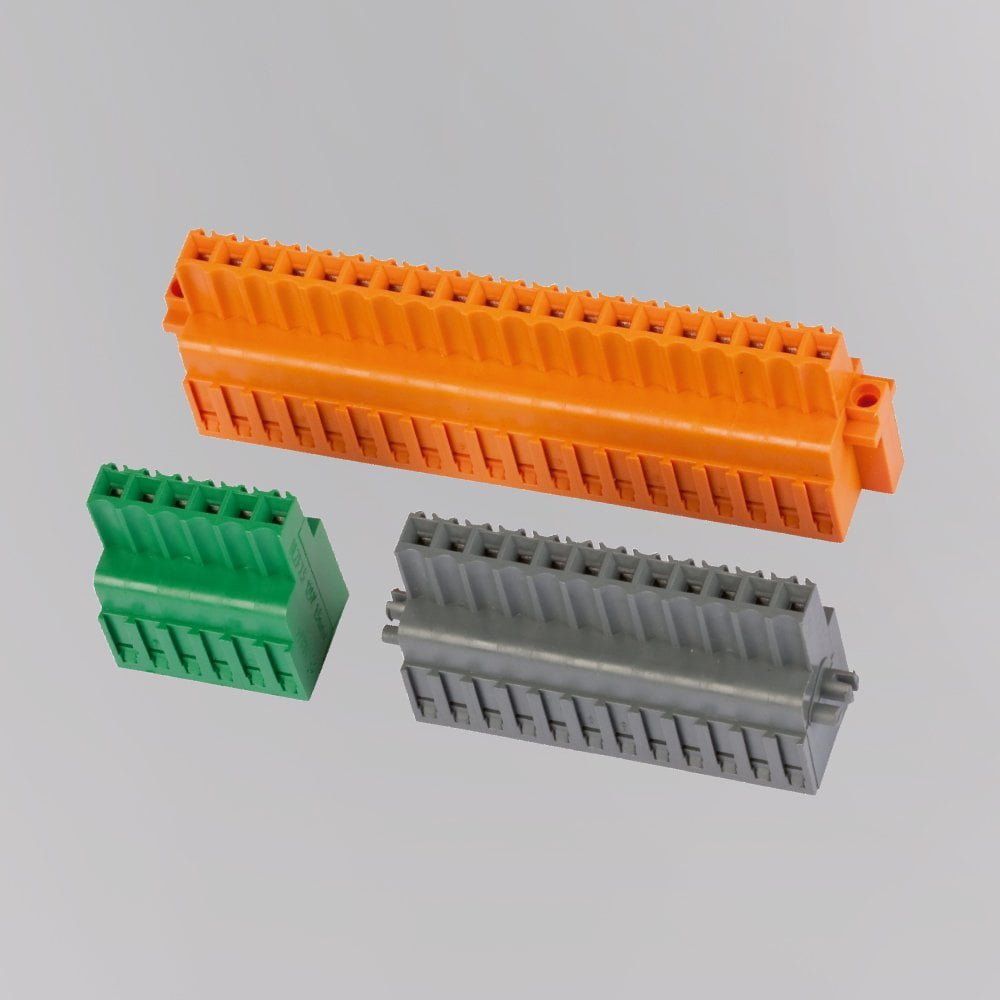

Case Study: Commercial Goods

Pin strip assembly with PIA SKT

Perfect serial production of products for signal, data and control currents, power network connection and power terminals.

In this type of assembly line system, the component itself serves as a transport medium through the machine. As a result, no additional workpiece carrier is necessary. The components are transported via so-called transport fingers from one processing step to the next. Several of these fingers in rows are called a “comb transport” system. With the very fast servo-controlled comb feed, coupled with real and virtual cam controls, we achieve maximum flexibility, keep setup times low and create the prerequisites for the production of small batch sizes with a high degree of utilization (OEE).

- Feed rates of 150 mm <100 ms

- Very high cycle rates

- Freely selectable thanks to servo-drive positions

- Minimal setup effort for processing

- Different product variants