Case Study: Commercial Goods

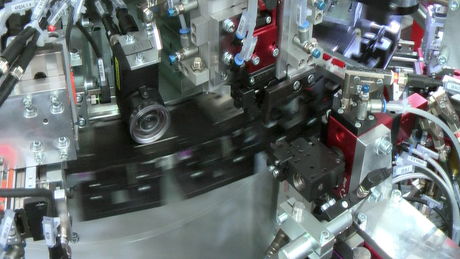

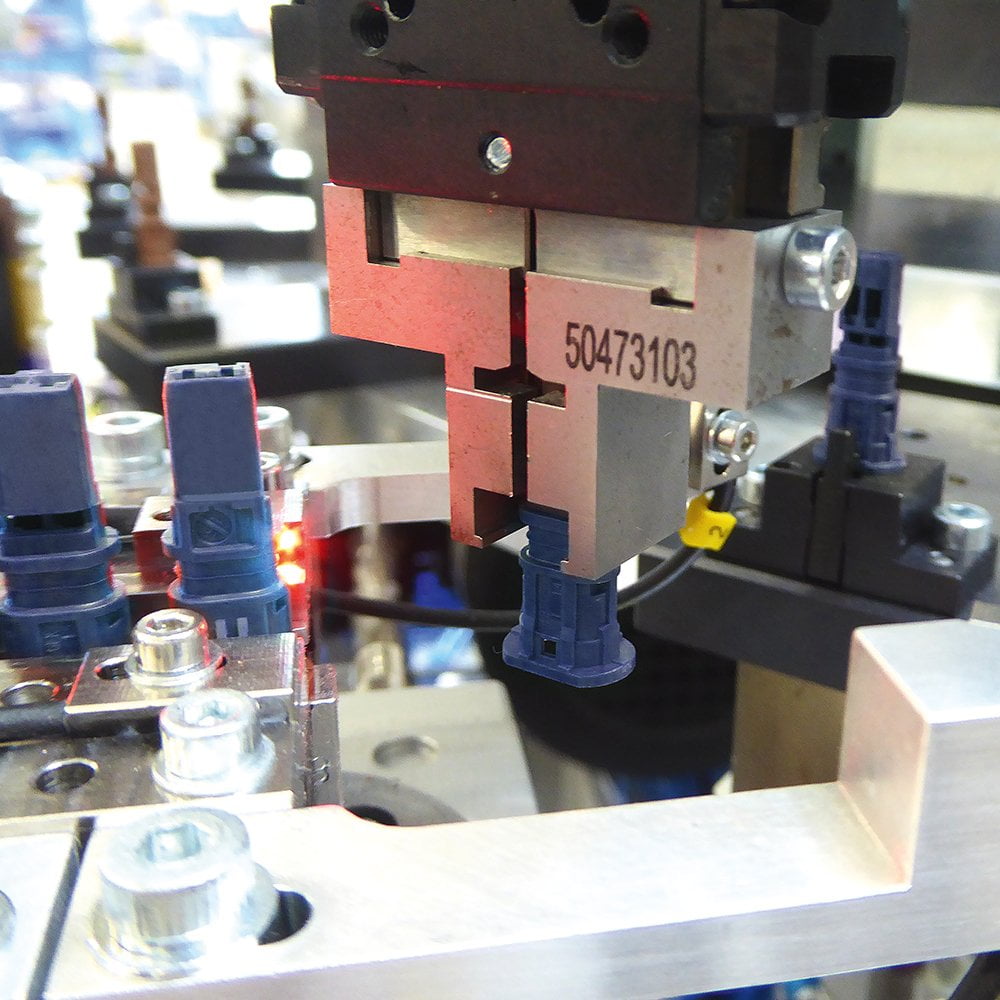

Connector and switch assembly with PIA EGM

Typical electronics: the assembly of small and smallest components in the smallest space.

The heart of the system is the central drive in the middle. It allows transfer movements (horizontal, vertical, rotating), the cycling of the rotating table and the process movements in the stations via an optional gear rim. Thanks to the use of cam technology and electric drives (slides, grippers), pneumatics can be largely dispensed with. This significantly improves the technical availability, facilitates troubleshooting and guarantees a higher overall level of economic efficiency. The strengths of the PIA EGM really come into their own when small components have to be processed very quickly and safely – with the greatest degree of precision and in large quantities.

- Workstations for 12 or 16 main positions plus 1 secondary station each

- Handling modules are guided and cam-controlled

- Feed modules have a cam-controlled drive

- Absolutely minimal compressed air consumption