E-Mobility as a megatrend in Automatisation

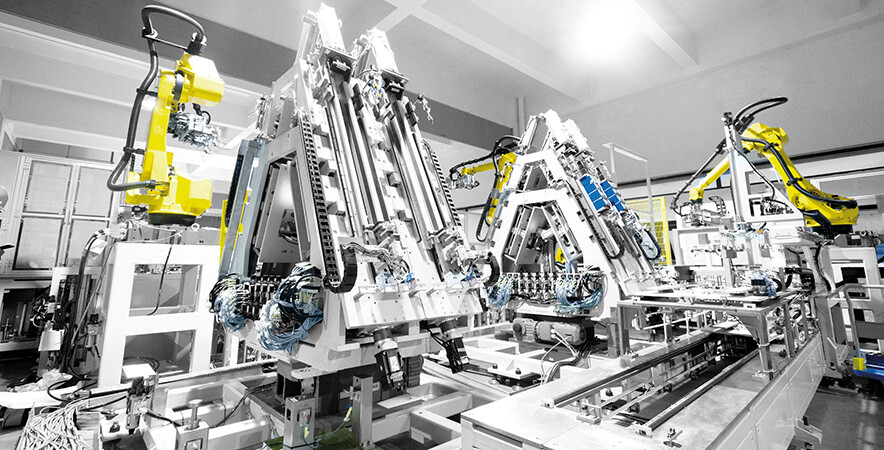

With the rapid rise of e-mobility, the automotive industry is facing increasingly demanding tasks. As a leading company in the field of automation technology, we offer customized production solutions to our premium automotive customers.

Markus Wagner, Senior Key Account Manager at PIA Austria, is a member of the newly formed battery team there. "In recent years, the demand from OEMs and Tier-1s for e-drive trains as well as battery systems has increased substantially," he says. The topic of e-mobility is a big game changer, both for our customers and as well for our company. It appears that the classic powertrain will be replaced by the alternative electric powertrain in the future. Here at PIA, we recognized the trend towards e-mobility early on, adapted processes and comprehensively analyzed our customers' requirements. Together with OEM and Tier 1 customers, new assembly processes and test procedures are now being developed. We consult with our clients early, when the planning phase starts as well as contribute our expertise to the formulation of requirements.

PIA Automation delivers battery production to Europe

Among other things, we also support our customers in setting up battery production in Europe. E-Mobility would not be conceivable without reliable, high-performance battery systems and although we face new challenges for manufacturing, PIA has established itself to meet the needs of its customers. Currently, it is possible to process three types of battery cells into individual modules. These modules consist of either round cells, prismatic cells or pouch cells that subsequently form battery packs. The interaction of the battery cell, module and packaging system must be perfectly matched to ensure a high-quality end product. Thanks to years of experience with highly complex assembly processes, we are well positioned for the future in e-drives and battery systems.

MARKUS WAGNER, SENIOR ACCOUNT MANAGER PIA AUSTRIA

"The quality of the product is always our first priority - the battery must be 100 percent in order and work prefectly. Because of the high voltage battery parts, employee safety is also essential during the proecesses of battery production. Each of our employees are specially trained for these highly complex processes," says Markus Wagner.