High-precision laser marking for injection pens

PIA Automation has developed and delivered a high-precision UV laser marking and inspection line for insulin pens. The solution replaces conventional pad printing with laser technology at a leading U.S. medical device manufacturer. It operates significantly more efficiently than previous medical manufacturing systems while meeting stringent environmental and regulatory requirements.

Technological superiority through laser instead of pad printing

Sustainable and resource-efficient

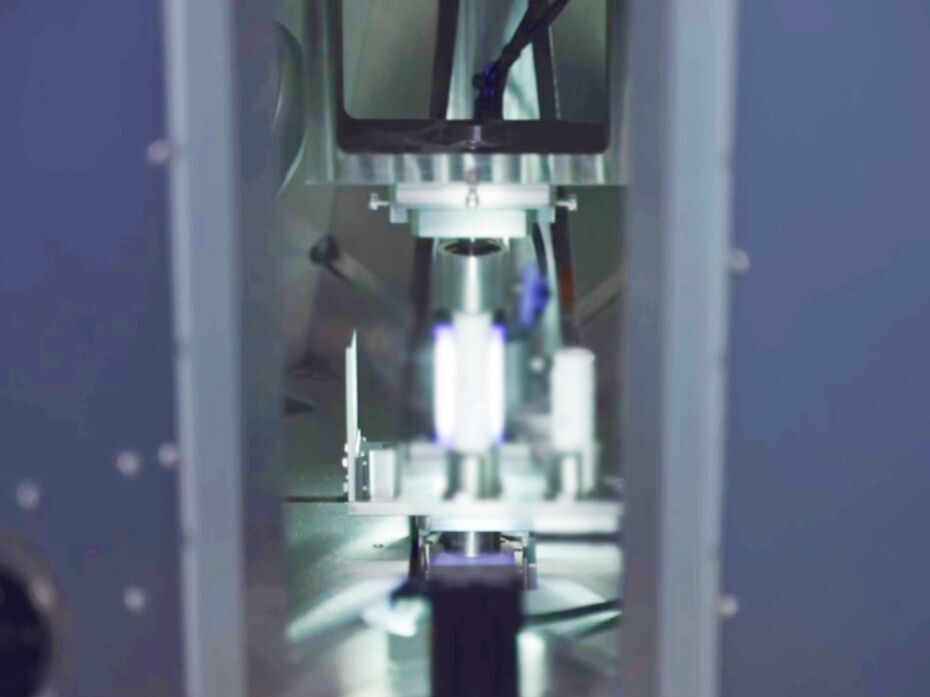

The process is based on UV laser marking and operates without consumables such as inks or solvents. Printing waste and environmentally harmful emissions are eliminated from the outset. As a result, the solution overcomes the ecological drawbacks of pad printing while meeting the growing demand for sustainable, low-carbon industrial processes.

Beyond its environmental benefits, eliminating consumables significantly reduces ongoing operating expenses as well as the need for manual intervention. Plate changes and maintenance-related downtime are minimized. At the same time, insulin pen output increases substantially, resulting in an overall sustainably optimized total cost of ownership.

Rigorous process standards

As a key equipment line for one of the top-grossing U.S. companies in the medical technology sector, the system meets the highest requirements for marking medical components. Compared to traditional pad printing, it offers clear technological advantages by eliminating the weaknesses of conventional processes and providing a stable, fully integrated marking solution with a high level of process reliability in full compliance with stringent medical device regulations.

Technological expertise for medical excellence

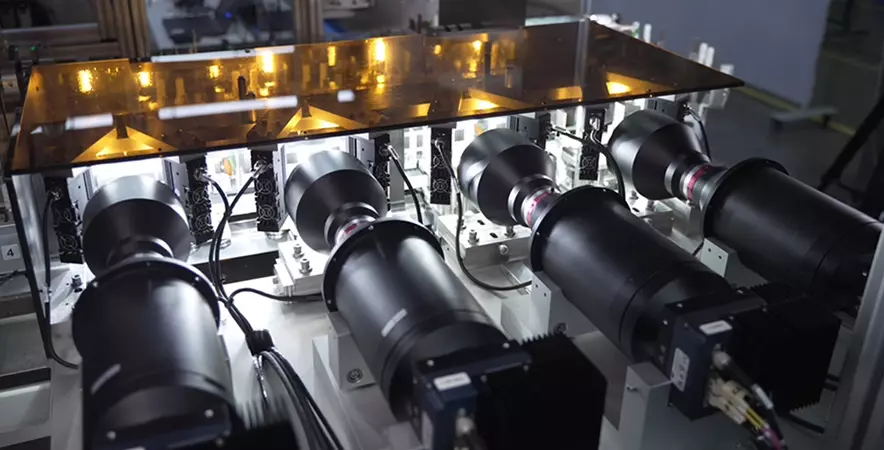

High-performance production enabled by magnetic levitation technology

The production line utilizes a magnetic levitation transfer system, replacing conventional rotary indexing concepts. It processes nine product variants and achieves a cycle time of 0.75 seconds per component – equivalent to 80 parts per minute. Compared to the customer’s previous solution, which produced 30 parts per minute, the new system nearly triples capacity while delivering exceptional precision.

Through optimized mechanical design and advanced algorithms, the system marks each component with an accuracy of ±0.2 mm and performs measurements with a precision of ±0.02 mm. This enables compliance with tolerance requirements in the double-digit micrometer range and ensures consistently high product quality.

Designed for reliable 24/7 operation

The system is designed for continuous high-volume operation in medical production environments, combining mechanical cam control with magnetic levitation technology. This hybrid architecture delivers both flexibility and operational reliability while meeting stringent requirements for uptime and process stability.

Regulatory compliance is a fundamental prerequisite for the international deployment of medical equipment. For this reason, PIA addressed stringent European and U.S. regulatory requirements from the earliest stages of development.

Accordingly, the production line completed comprehensive verification and conformity assessments covering material safety, equipment stability and camera-based validation systems. It complies with international standards including CE, GAMP, FDA 21 CFR Part 820, and ISO 13485, enabling the client to scale global production capacity.

Strengthening partnership and advancing technology

Following the successful implementation, a second identical system is already under discussion. The realization of this laser marking and inspection solution not only demonstrates PIA’s technological innovation in high-precision medical manufacturing but also highlights the company’s strong focus on the demands of advanced medical production.

Building on this success, PIA will further intensify its R&D activities in the life sciences and medical technology sectors, expand application areas for advanced medical systems, and provide international manufacturers with integrated, intelligent production solutions. The goal is to consistently drive process optimization, quality improvement, system stability, and sustainable development in medical manufacturing.