Virtual commissioning for cleaning systems

Sparkling clean flange surfaces

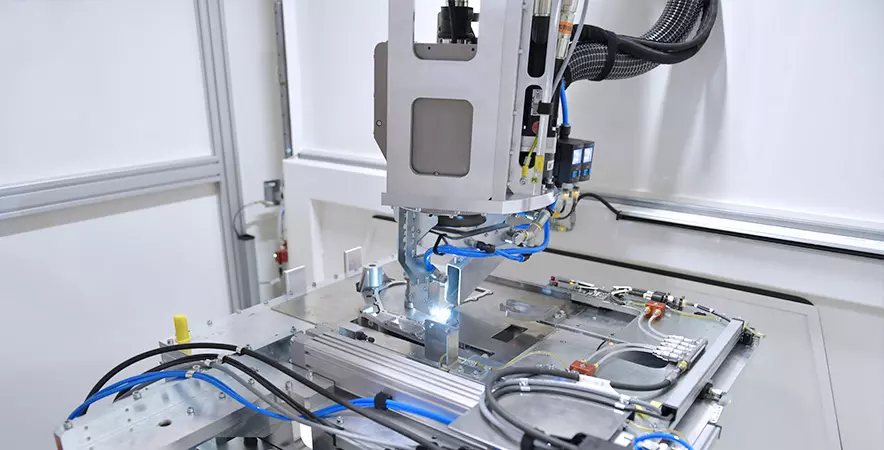

Laser cleaning system for e-motor production automotive

The final assembly of electric drives in the automotive industry requires maximum precision - and absolute cleanliness. Any impurities remaining on the flange surfaces from the production process pose a risk to the tightness of the motor housing and jeopardize its function and durability. PIA Automation has therefore developed an automated laser cleaning system for electric motor production lines. Modeled as a digital twin in the design phase, its configuration adapts to the respective local conditions. Virtual commissioning makes it possible to test functions in advance in the simulation model. Integration into existing systems has also been tried and tested.

When the individual components of electric drives are joined together to form a unit, the flange surfaces of the components must not only be clean, but absolutely spotless. Even the smallest particles of oil, grease, dust, or drilling emulsion can cause the aluminum components to not seal completely after joining and bolting. In this case, water could penetrate and lead to short circuits. On many production lines today, this cleaning process is carried out manually with a cleaning cloth and alcohol solution; quality control requires piece by piece visual inspection - a process that is time-consuming and not reliable. It is better to automate this important production step for product quality with a laser cleaning system.

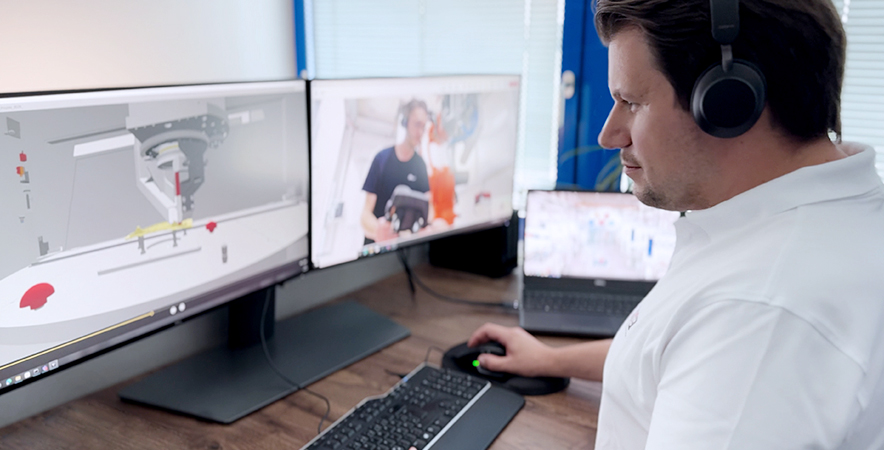

“In one application, we integrated laser cleaning into an existing system. Modeling the system as a digital twin allowed us to precisely adapt the robotics to the specific spatial conditions and achieve a significant improvement in software quality.”

Markus Larcher, Sales Application Engineer at PIA

Virtual commissioning creates new possibilities

Modeling digital twins of complex systems and using them to virtually test and optimize functions is an innovative method in plant engineering. Virtual commissioning provides a precise picture of a planned system's real processes even before the first machine part is installed. The simulation can analyze errors in the conceptual phase and identify the causes of quality defects in the end product, eliminating the need to produce sample parts. Design changes or trials of alternative solutions can be quickly and risk-free visualized in the digital twin and validated virtually.

Compared to traditional commissioning with the process steps of design - production - assembly and installation - ramp-up, system implementation is significantly shorter with the virtual commissioning tool. Particularly in the ramp-up phase of a new plant, time savings of between 30 and 50 percent can be achieved. This is partly because the product quality can already be considered in the simulation phase, and the error rate can be minimized.

In the application mentioned above, the assembly system for the electric motors was already in operation. To retrofit the automated laser cleaning system, PIA's design engineers proposed a second level for the cleaning system: A lift system transports the components upward-, and a transfer system feeds them to the cleaning cells. The cleaning itself is carried out fully automatically using a Trumpf laser: a six-axis robot with attached optics maneuvers the laser so that it precisely coats the flange surfaces and cleans them quickly and effectively. As there is a load-bearing hall column in the area of the cleaning system, the movement of the robots was adapted to the conditions so that there is no risk of collision. The ergonomics of the manual processing steps of insertion and removal were also optimized during the simulation phase.

Laser cleaning removes dirt, but it leaves traces

Although the high energy of the laser beams reliably removes dirt particles, lasering leaves behind dirt residue. These are removed residue-free via a blowing and suction device on the laser robot. A suction funnel collects the dirt immediately after cleaning. This configuration prevents the freshly cleaned contours from becoming contaminated again. The extracted residues remain in a closed system and are not released into the ambient air.

Conclusion: reliable, fast and cost-effective

Vehicle manufacturers benefit from a significant increase in process reliability during laser cleaning. If virtual commissioning is integrated into the system planning, considerable savings in time and resources can be made during the design phase and ramp-up.

“Automated cleaning with lasers shows how even supposedly small process steps can be automated efficiently and economically,” says Markus Larcher from PIA. The precise cleaning quality and short cycle time speak for themselves: human operators would not be able to achieve cleaning of a comparable quality manually. Automation increases the productivity of the line and thus enables higher quantities. The laser cleaning system takes the strain off the employees, leaving their hands free for value-adding work along the assembly line