Automation solutions

Welding plants

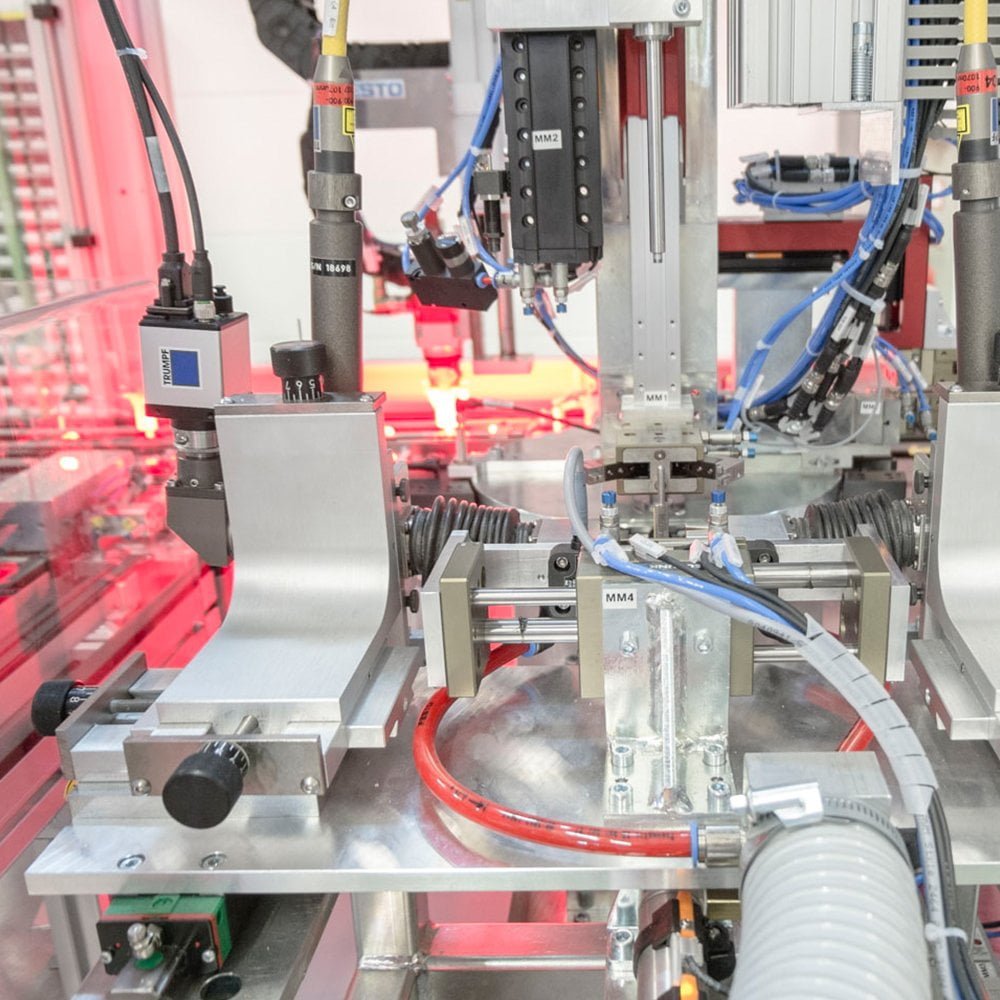

Welding has long been one of the most important methods in industrial production for producing permanent connections between components or for coating them by means of build-up welding. In some industries or products, this can only be done by hand, i.e. by trained specialists. However, recurring work on the same components can be automated, which not only reduces operating and personnel costs, but also generally ensures a higher production speed and throughput rate with consistently high quality, especially when small and filigree components are involved.

PIA has the solutions for automated welding

PIA realizes fully automatic systems with welding robots and turntables as well as clamping fixtures designed for different welding tasks, including resistance, arc and laser welding. We can either supply the corresponding cells as a single system - for example as a first step into the automation of welding work - or integrate them directly into your assembly and production lines as a supplement to existing systems.

Of particular note in this area is laser technology, which is advancing into ever new regions. Especially laser welding in the serial production of powertrain components - the drive trains of vehicles - is becoming increasingly important and has meanwhile established itself nationwide in the automotive industry.

Our modular systems grow with you

The modular design of our welding systems enables you as a user to solve highly specific tasks by means of automation or to react dynamically and promptly to significant changes in your production environment. PIA products grow with the needs and requirements of our customers and secure their competitive advantage without overstretching their budgets.

Like all our fully automated systems, PIA welding systems are intuitive, easy to operate and maintain. In this way we support you in your production and offer you sustainable process reliability.

Please contact us if you would like to know more about our fully automatic welding systems for different processes. We will be happy to advise you.