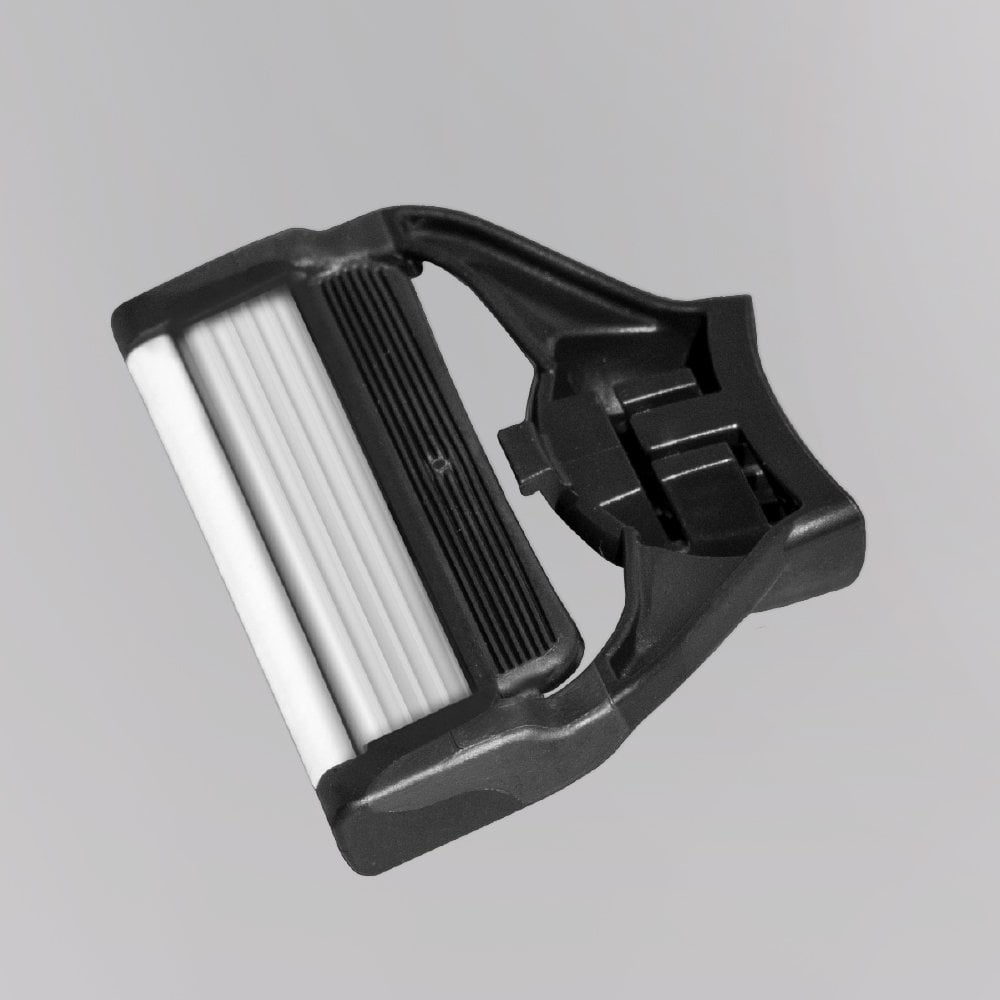

Case Study: Consumer goods

Assembly line system for 5-fold cutting units

Fully automated assembly, testing and packaging of 5-fold cutting units for safety razors.

Manufacturing facility with several connected PIA variable base cells, consisting of four interlinked base cells. Safety razors for women and men.

Processes:

- Automatic parts feeding

- De-stacking of curved blades

- Feeding sacrificial anodes from a roll and cutting them to length

- De-stacking trimmer blades and cutting them to contour

- Assembly of all components

- US welding

- Laser marking DMC and proofreading

- Image processing for surface, completeness and blade distance

- Packaging in dispensers

Cycle time: 60 parts/minute = 1 second per part